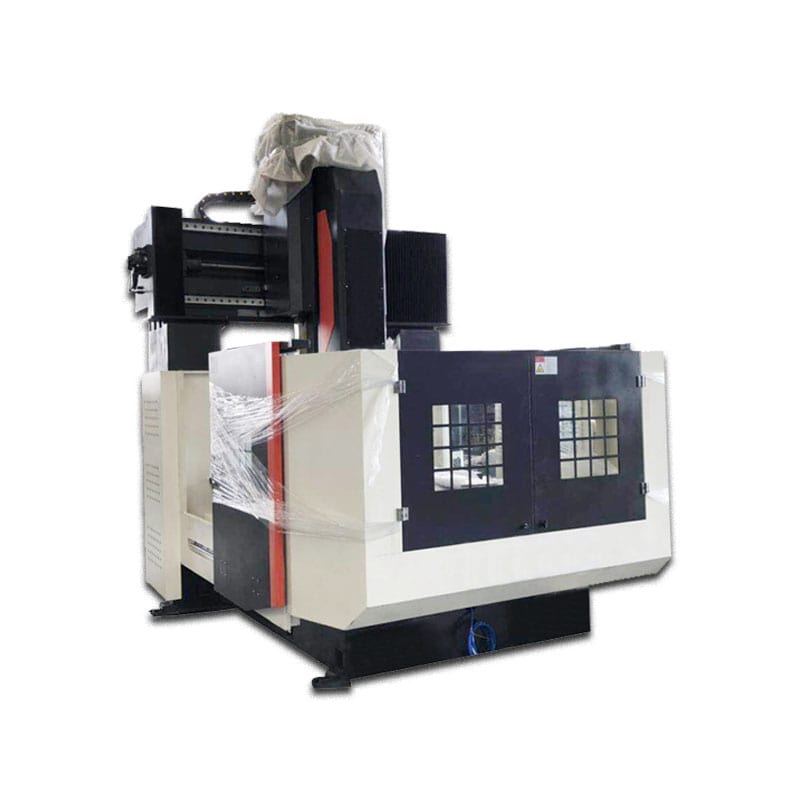

5 Axis Gantry Milling Machine GMC1090 gantry metal cnc milling machine

Product Description

5 Axis Gantry Milling Machine GMC1090 gantry metal cnc milling machine

CNC Gantry Milling Machine is suitable for milling, vertical planes, or diagonal grooves of large and medium -sized black metals or non -ferrous metal parts on various mechanicals

And according to the various improvements that the user needs, the same type of processing and manufacturing.

Video

Video

CNC Gantry Milling Machine Safety Operation Regulations

1. CNC Gantry Machine Center works should be clamped with pressure plates, screws or special tools. The use of a wrench is not allowed to add a tube to avoid slipping the injury.

2. Gantry Metal CNC Milling Machine must be clamped, otherwise it is not allowed to drive.

3.5 Axis Gantry Milling Machine before work, check the operating of the machine tool transmission and install the machine tool baffle to run.

4. Gantry Type Machine Center Milling various workpieces, especially when coarse milling, should start slowly cutting.

5. When gantry machining center mobile workbench and blade, the fixed screw should be released first.

6. When CNC Drilling and Milling Machine is loaded and unloaded, a copper hammer or mallet should be used to prevent the knife fragments from flying out of the injury.

Video

Gantry Metal CNC Milling Machine

1. CNC Gantry Machine Center Machining is suitable for fine processing of non -ferrous metal parts; because the precision mechanical parts processing material itself has a low hardness, good plasticity, and other processing methods are difficult to obtain a smooth surface.

2. Gantry Metal CNC Milling Machine processing is suitable for the plane of large workpieces for mechanical processing. CNC Longmen milling machines can also process spatial curved surfaces and some special parts.

3. 5 AXIS Gantry Milling Machine's CNC intelligent operation not only reduces the labor intensity of workers, also improves production efficiency, guarantees processing accuracy, and is the best choice for the metal plane processing industry.

Video

| Item | Name | GMC1090 |

|---|---|---|

| Structure type | Fixed beam gantry structure | |

| Gantry width(mm) | 980 | |

| Worktable | Worktable load (KG) | 2000 |

| Worktable size (mm) | 900*1000 | |

| T-slot width | 18mm | |

| X.Y.Z Axis | Travel (mm) | 900*1000*450(optional) |

| X.Y axis fast moving speed(no load)( mm/min) | 8000-15000 | |

| Z axis fast moving speed(mm/min) | 7000-10000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 | |

| Spindle | Spindle motor power | 7.5KW Servo |

| Spindle motor speed(r/min) | 0-8000 | |

| Dimensions | L*W*H(m)(About) | 2.9*2.3*2.8 |

| Machine weight | (About)(T) | 6 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More