GMC1417 gantry type machine center features introduction

The cnc gantry milling machine meets the key processing needs of oversized parts in key areas such as aerospace, power generation equipment, and automobiles; high-speed and fine CNC lathes, processing intermediates and other products are widely used in automotive, aerospace, electronics, military and other professional fields. And it has driven many small and medium-sized companies to upgrade their equipment and upgrade their industries.

Product Description

GMC1417 gantry type machine center features introduction

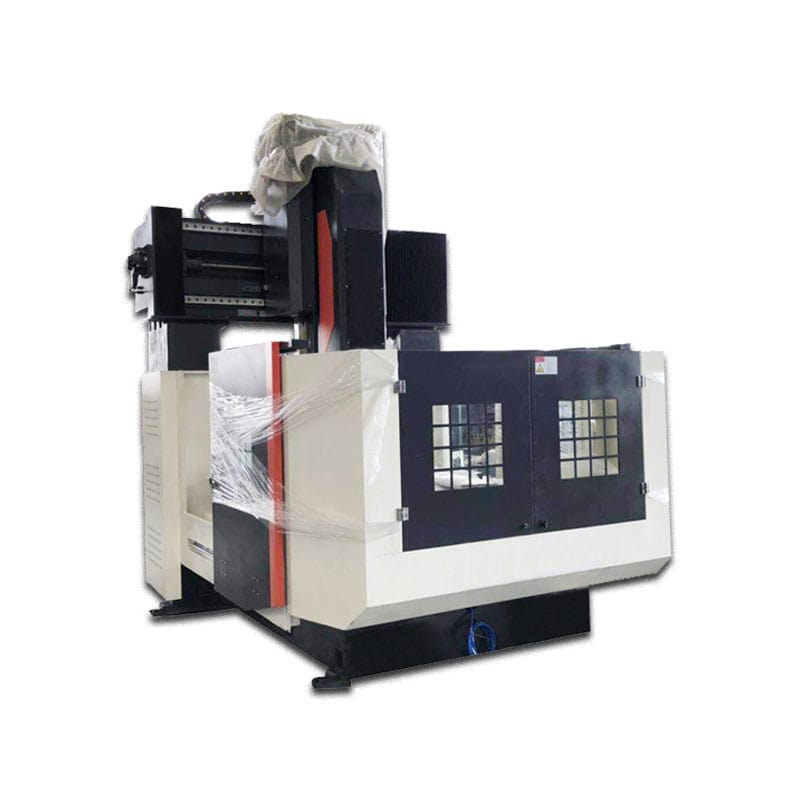

In the overall structure, the cnc gantry milling machine is a gantry structure: the components of the gantry frame include double rods, connecting beams, transverse slides, milling headrests, etc.

It can be said that CNC Gantry Machining Center is mainly a mechanical processing equipment reasonably developed through materials such as machinery, electricity, liquid and advanced technology.

Gantry metal cnc milling machine is mainly used for semi-finishing and finishing in heavy machinery, locomotives, shipbuilding, power generation, machine tools, printing, molds and other industries.It can also be treated rudely.

Video

Gantry metal cnc milling machine function

5 Axis Gantry Milling Machine has a variety of functions, such as boring machine, drilling machine, etc., coupled with high-precision rotary table, right-angle milling head and other functional accessories, can complete five-sided processing, and can be directly used in metallurgy, energy, electric power and other industries.

The main drive of the gantry type machine center adopts the stepless speed regulation of the switch reluctance motor (planer, milling gear box) worktable, and the speed regulation range is wide, which can meet various speed requirements of planing and milling.

Gantry Machining Center can process horizontal planes, vertical planes, inclined planes, T-slots, arc grooves, rail combination surfaces and racks of various materials.

Video

Application field

1. Metallurgical equipment manufacturing industry: for continuous casting and rolling equipment

2. Construction machinery manufacturing industry: for gearboxes, excavating arms, car bodies, engines and other components

3. Shipbuilding Industry: For Diesel Blocks

4. Automobile manufacturing industry: for vehicle components: engines, which require high-efficiency, high-performance, special-purpose CNC machine tools and flexible production lines; for spare parts processing

Video

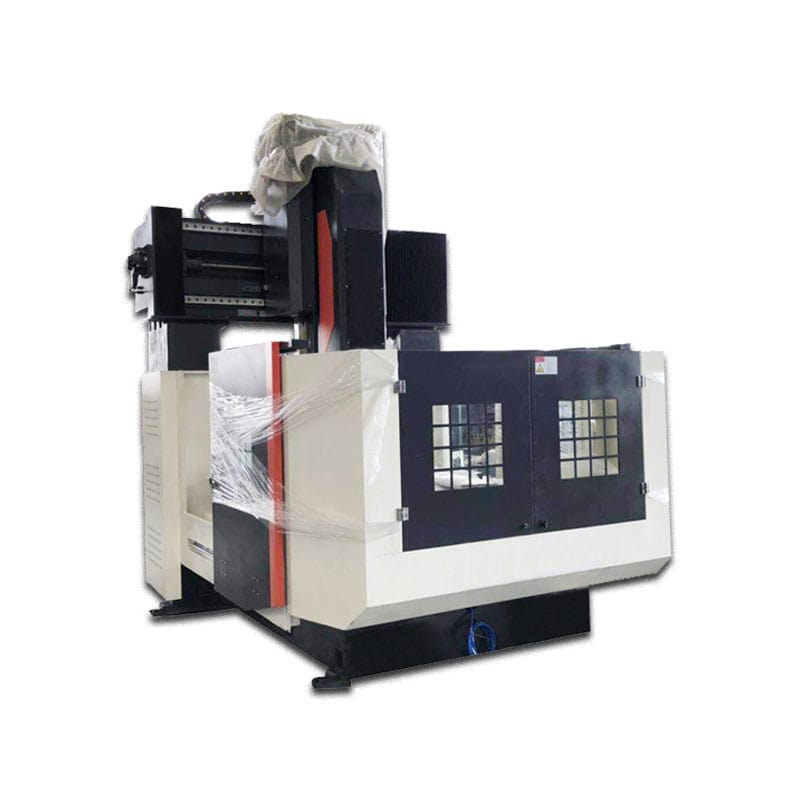

| Item | Unit | Specs | |

|---|---|---|---|

| Gantry width | mm | 1280 | |

| Worktable | Worktable load | KG | 2500 |

| Worktable size | mm | 1400*1700 | |

| Worktable size | mm | 18 | |

| X.Y.Z Axis | Travel | mm | 1400*1700*450 |

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle | Spindle power | KW | 7.5 |

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H | m | 4*2.3*2.6~2.9 |

| Weight | T | 9.5 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More