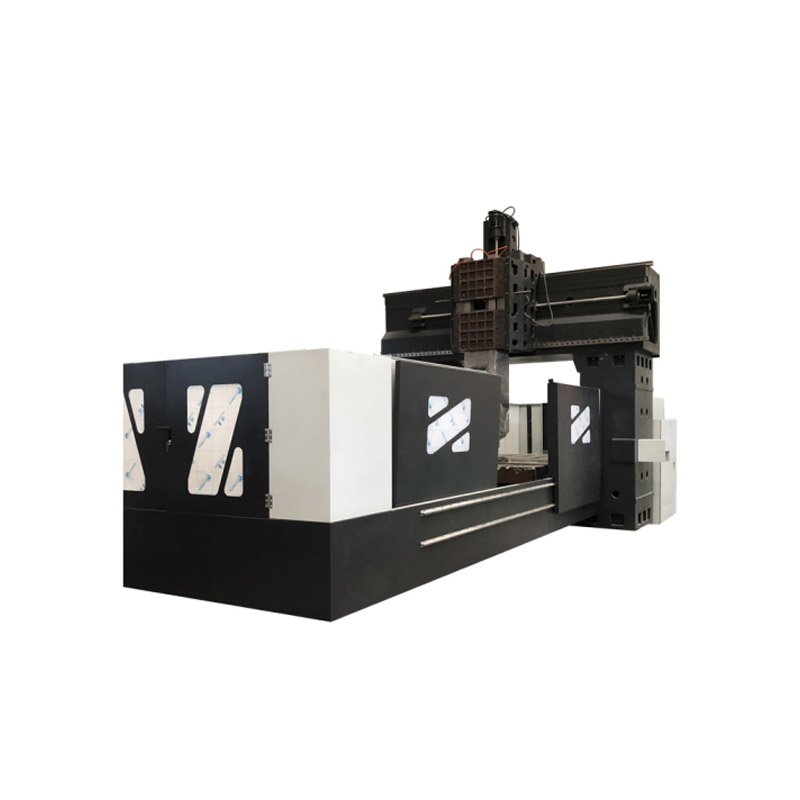

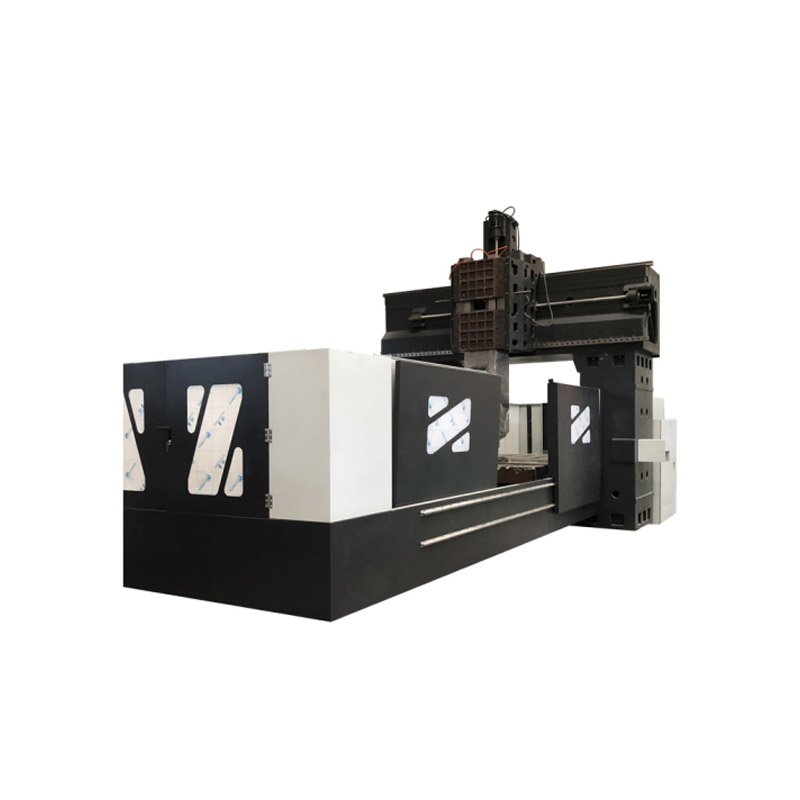

Gantry metal cnc milling machine GMC1825 gantry type machine center

cnc gantry milling machine is an advanced processing equipment with high degree of automation, complex structure and high price. It plays a huge role in modern industrial production. In order to give full play to the effect of CNC Gantry Machining Center, do a good job in the daily maintenance and maintenance of the machine tool. It is very important to reduce the failure rate of gantry metal cnc milling machine.

Product Description

Gantry metal cnc milling machine GMC1825 gantry type machine center

Provides GMC1825 cnc gantry milling machine for various industries that require machining tools. Using multiple tools simultaneously, the CNC Gantry Machining Center maximizes productivity and output. Using multiple cutters increases efficiency while maintaining precision cutting. The gantry metal cnc milling machine is so named because the gantry is located above the horizontal bed.

Video

The vibration fault caused by the electrical control of the cnc gantry milling machine machine tool is random. The following methods can be used to judge:

The vibration fault caused by the electrical control of the cnc gantry milling machine machine tool is random. The following methods can be used to judge:

1. Separation method. For the feed or spindle motion of the built-in motor, the coupling between the motor and the transmission mechanism should be loosened or suspended in a neutral position, and run at various speeds. The cause of the vibration should be judged whether the motor runs smoothly.

2. Parametric method. CNC Gantry Machining Center In the closed-loop system, due to improper setting (or adjustment) of parameters (such as loop gain, acceleration and deceleration time constant, etc.), the parameters need to be re-adjusted. When a vibration failure occurs in the gantry metal cnc milling machine, some parameters should be appropriately changed, and at the same time, observe whether the vibration phenomenon changes. Some of these parameters are given in the form of machine parameters, and some are adjusted by the potentiometer on the driver.

3. External drive mode. For the vibration caused by the operation of the spindle of the 5 Axis Gantry Milling Machine, lathe, milling machine and other machine tools, an ordinary AC motor (or a DC motor can be driven by the electric welding machine power supply) can be used to drive the spindle to rotate through the coupling to determine the cause of the vibration. Pay attention to the concentricity of the main shaft and the motor shaft. and release the brake on the spindle.

4. Current measurement method. Vibration failures caused by mechanical causes of gantry type machine centers usually cause torque changes. When measuring the motor current during constant speed no-load operation, it can be judged by observing whether its change is consistent with the vibration.

Video

Application areas of CNC Gantry Machining Center

1. Aviation industry: for parts such as aircraft wings, fuselage, tail, etc. and engine parts

2. Railway locomotive manufacturing industry: for high-speed railway locomotive body, axles, wheels and other parts

3. Weapons manufacturing industry: for tanks, armored vehicles, bullets, guns, cores and other products

4. Mould manufacturing industry: for automobile panel moulds, die-casting moulds, forming extrusion moulds, etc.

Video

| Item | Name | GMC1825 |

|---|---|---|

| Structure type | Fixed beam gantry structure | |

| Gantry width(mm) | 1880 | |

| Worktable | Worktable load (KG) | 6000 |

| Worktable size (mm) | 1800*2500 | |

| T-slot width | 22mm | |

| X.Y.Z Axis | Travel (mm) | 1800*2500*700(Optional) |

| X.Y axis fast moving speed(no load)( mm/min) | 10000 | |

| Z axis fast moving speed(mm/min) | 7000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 | |

| Spindle | Spindle motor power | 15KW Servo |

| Spindle motor speed(r/min) | 0-6000 | |

| Nasal end to table distance (about)(mm) | 150-850 | |

| Dimensions | L*W*H(m)(About) | 7.5*3.0*3.7 |

| Machine weight (About)(T) | 24 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More