CNC milling machine GMC2030 gantry type machine center

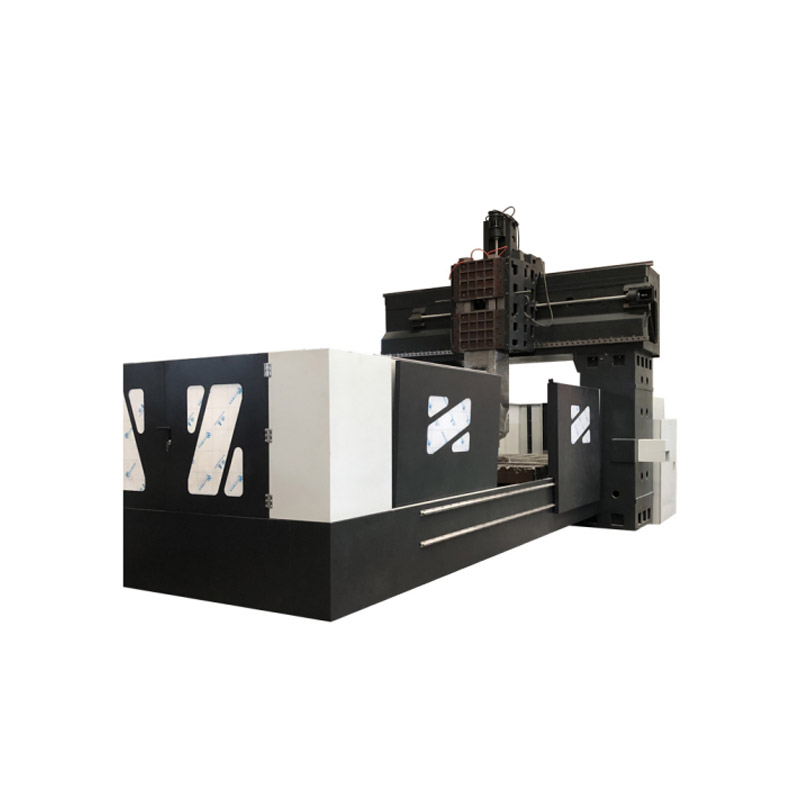

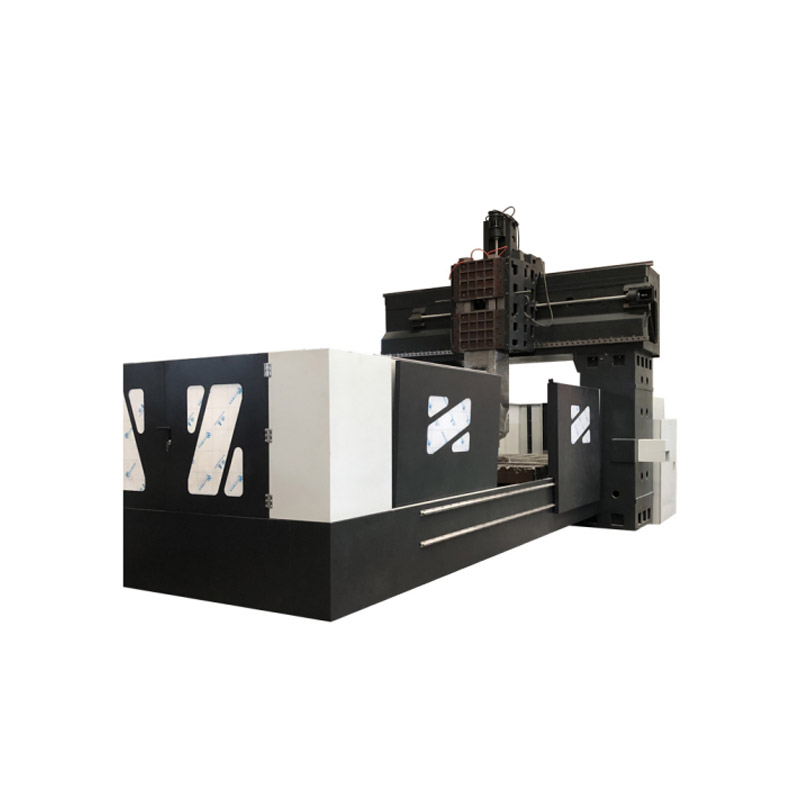

CNC gantry milling machines have the ability to cut aluminum and other metals, as well as the speed to cut a wide variety of plastics and other lightweight materials. The rigid steel structure of the CNC gantry milling machine provides a very stable cutting platform, and the thick aluminum table is standard.

Product Description

CNC milling machine GMC2030 gantry type machine center

The cnc gantry milling machine has the ability to cut aluminum and other metals, as well as the speed to cut plastic and other lightweight materials.

The CNC Gantry Machining Center can handle large sheets with ease, or it can machine thousands of small parts.

The mobile guard of the gantry metal cnc milling machine protects the operator from chips and coolant and keeps the working space clean.

Video

Features of gantry metal cnc milling machine

1.5 Axis Gantry Milling Machine box structure design, suitable for limited working space, integrated design of worktable and column, provides stable and fast feeding performance, and meets the requirements of precision mold and aluminum cutting.

2. The combination of gantry type machine center column, bed and worktable in one-piece casting, according to the pyramid-shaped weight distribution of spindle, guide rail, beam and bed.

3. The Gantry Machining Center direct drive spindle has low noise, low backlash, low vibration and low power consumption, ensuring high workpiece surface accuracy after rapid cutting.

4. The cnc drilling and milling machine has a low table height, a closer operating area, and a wider door width, which are user-friendly designs.

5.CNC milling machine chain chip conveyor (standard) can effectively remove iron filings.

Video

Precision Machining of Aero-Engine Components

We prioritize accuracy from the start to ensure every part is machined to tight tolerances.

Our machines are exceptionally rigid and utilize the latest automation, software and robotics for optimum precision and repeatability.

For each project, we draw on a long history and extensive experience.

Our robust equipment is flexible to meet your requirements, so you can design a custom machine to meet your needs. Milling, turning, profiling – everything is possible with consistent quality.

With multiple configurations and smart systems, you can create a safety line that suits you.

Reduce cycle times with automated clamping solutions and clever clamping devices.

Take advantage of Industry 4.0 technologies to ensure optimal, repeatable end product quality.

Optimum throughput even on large or complex components.

Video

| Item | Unit | Specs | |

|---|---|---|---|

| Structure type | Fixed beam gantry type | Resin sand casting | |

| Gantry width | mm | 1280 | |

| Worktable | Worktable load | KG | 2500 |

| Worktable size | mm | 2000*3000 | |

| T-slot width | mm | 18 | |

| X.Y.Z Axis | Travel | mm | 2000*3000*450 |

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle | Spindle power | KW | 7.5 |

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H | m | 4*2.3*2.6~2.9 |

| Weight | T | 11 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More