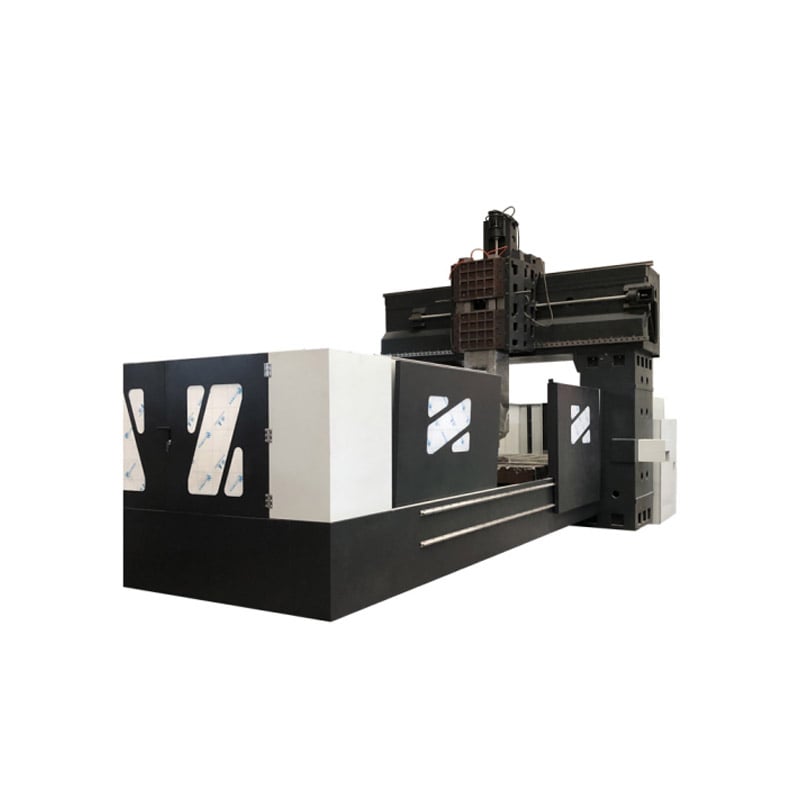

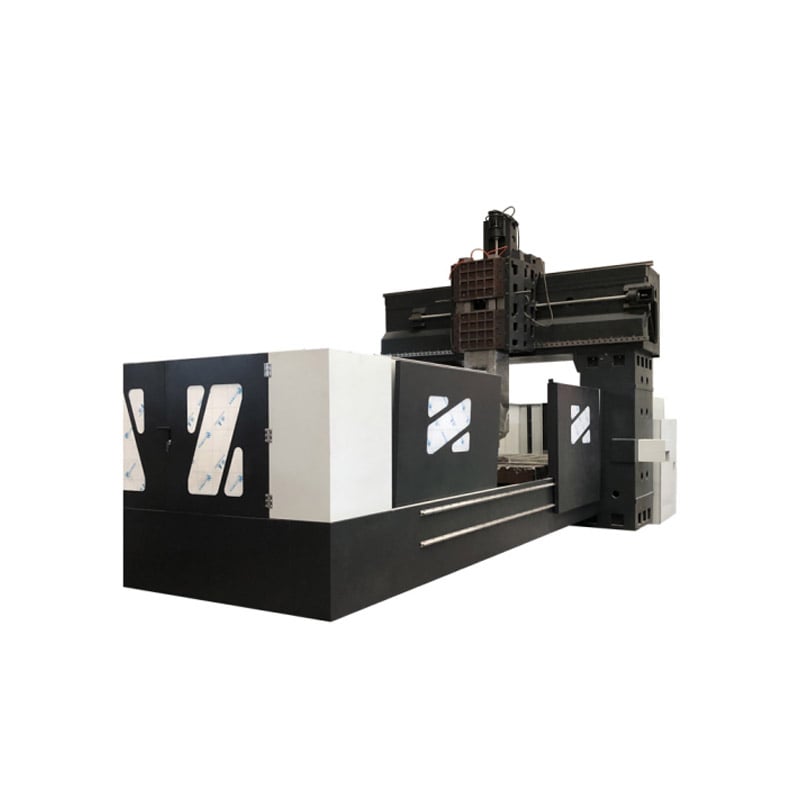

Gantry Milling Machine GMC2530 gantry metal cnc milling machine

Product Description

Gantry Milling Machine GMC2530 gantry metal cnc milling machine

Product Description

On the cnc gantry milling machine, multiple milling cutters can be used to machine the surface at the same time, and the machining accuracy and production efficiency are relatively high.

The CNC Gantry Machining Center is suitable for machining flat and inclined surfaces of large workpieces in batch and mass production.

Video

Features

1. The gantry type machine center is fixed by the gantry frame, the worktable is movable structure, and the beam guide rail adopts a stepped structure. Rigid.

2. Multiple reinforcement ribs are arranged inside each part of Gantry Machining Center, and the guide rail adopts the support structure of heavy-duty roller guide rail, so that the machine tool can obtain high rigidity and long-term stable precision.

3. The Z-axis ram of the cnc gantry milling machine can be in the form of a linear rail or a hard rail, which can be selected by the customer according to the processing requirements.

4.CNC milling machine can be equipped with gear box to enhance cutting torque.

Video

Matters needing attention

When using the gantry metal cnc milling machine to process parts, you should also pay attention to wearing protective clothing and pay attention to safe operations during processing. 5 Axis Gantry Milling Machine processing equipment is fixed and installed, and a dry and ventilated environment should be selected. The equipment cannot be used in a humid environment. In addition, if the staff finds abnormal noise during the production process, it is necessary to check the working condition of the equipment in time.

Video

| Item | Unit | Specs | |

|---|---|---|---|

| Structure type | Fixed beam gantry type | Resin sand casting | |

| Gantry width | mm | 1280 | |

| Worktable |

Worktable load

|

KG

|

2500

|

| Worktable size | mm | 2500*3000 | |

| T-slot width | mm | 18 | |

| X.Y.Z Axis |

Travel

|

mm

|

2500*3000*450

|

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle |

Spindle power

|

KW

|

7.5

|

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H |

m

|

4*2.3*2.6~2.9 |

| Weight | T | 13 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More