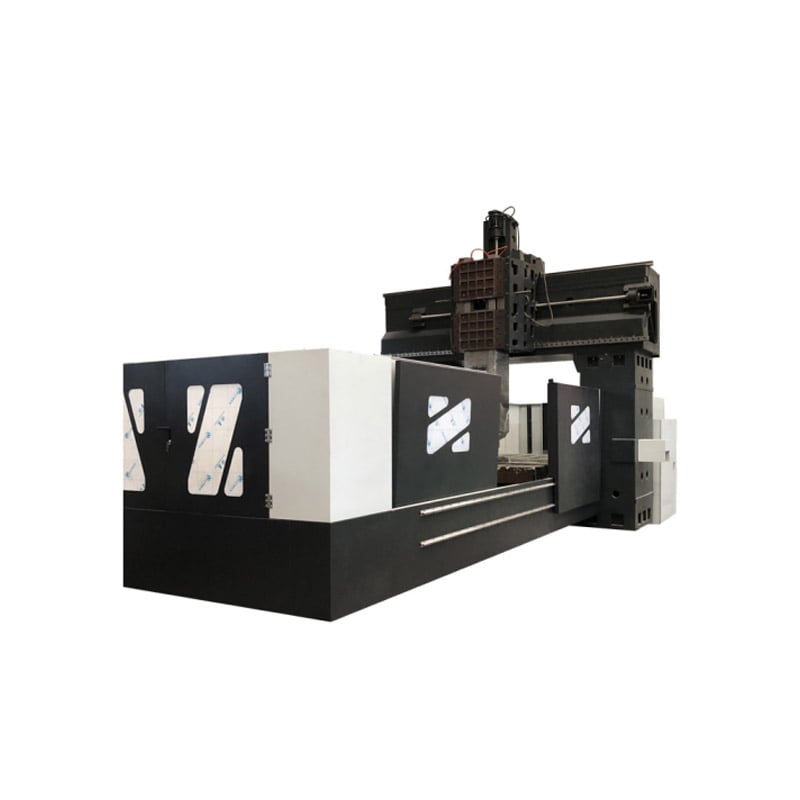

Double Column Milling Machine GMC2535 gantry type machine center

Product Description

Double Column Milling Machine GMC2535 gantry type machine center

Product Description

The main milling head of cnc gantry milling machine has the functions of milling, boring, drilling, countersinking, tapping, etc., Exclusively fit for large sized die-mould, tool room, aerospace and precision engineering component.

The CNC Gantry Machining Center is equipped with the attachment milling head to realize one-time clamping of the workpiece, and the installation of the right-angle milling head can realize five-sided machining.

Video

Features of cnc gantry milling machine

1. The CNC Gantry Machining Center adopts the gantry fixed beam frame structure, which maintains good rigidity and precision for a long time, with large torque and good dynamic characteristics. It fully absorbs the international advanced machine tool design concept according to the processing needs.

2. The key parts of the gantry metal cnc milling machine include the bed, column, beam, saddle, ram, and worktop, all of which are made of high-strength resin sand, high-strength and high-quality cast iron, which can withstand heavy cutting and maintain long-term accuracy and high stability .

3.5 Axis Gantry Milling Machine thermally symmetrical headstock, high-precision angular contact bearings are installed on the head and tail of the spindle to effectively ensure rigidity and precision. Rigidity is further enhanced by the adoption of a spindle with an enlarged diameter and thickness. The spindle is driven by a high-power motor, with high horsepower and high torque, which can achieve high-precision heavy cutting even at low speed.

4. The feeding system of gantry type machine center adopts the ball screw with enlarged diameter and pre-stretching, which increases the rigidity of the screw and can effectively prevent the thermal deformation of the screw.

5. Gantry Machining Center screw type and chain type automatic chip removal structure are combined to ensure smooth chip removal.

6. The X/Y axis of the cnc drilling and milling machine adopts the super-heavy-duty guide rail, and the Z axis adopts the rectangular hardened plastic-pasted guide rail, which has low wear and high load, ensures the long-term use accuracy of the machine tool, and can greatly improve the accuracy and precision of cutting. rigidity.

Video

Application field of gantry metal cnc milling machine

1. Railway locomotive manufacturing industry: for high-speed railway locomotive body, axles, wheels and other parts.

2. Weapons manufacturing industry: for tanks, armored vehicles, bullets, guns, cores and other products.

3. Electronic information equipment manufacturing industry: for high-end electronic product casings, motor rotor stators, motor casing covers, etc.

4. Metallurgical equipment manufacturing industry: for continuous casting and rolling equipment.

5. Construction machinery manufacturing industry: for gearboxes, excavating arms, car bodies, engines and other components.

Video

| Item | Unit | Specs | |

|---|---|---|---|

| Structure type | Fixed beam gantry type | Resin sand casting | |

| Gantry width | mm | 1280 | |

| Worktable |

Worktable load

|

KG

|

2500 |

| Worktable size | mm | 2500*3500 | |

| T-slot width | mm | 18 | |

| X.Y.Z Axis |

Travel

|

mm

|

2500*3500*450

|

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle |

Spindle power

|

KW

|

7.5

|

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H | m | 4*2.6*2.6~2.9 |

| Weight | T | 13 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More