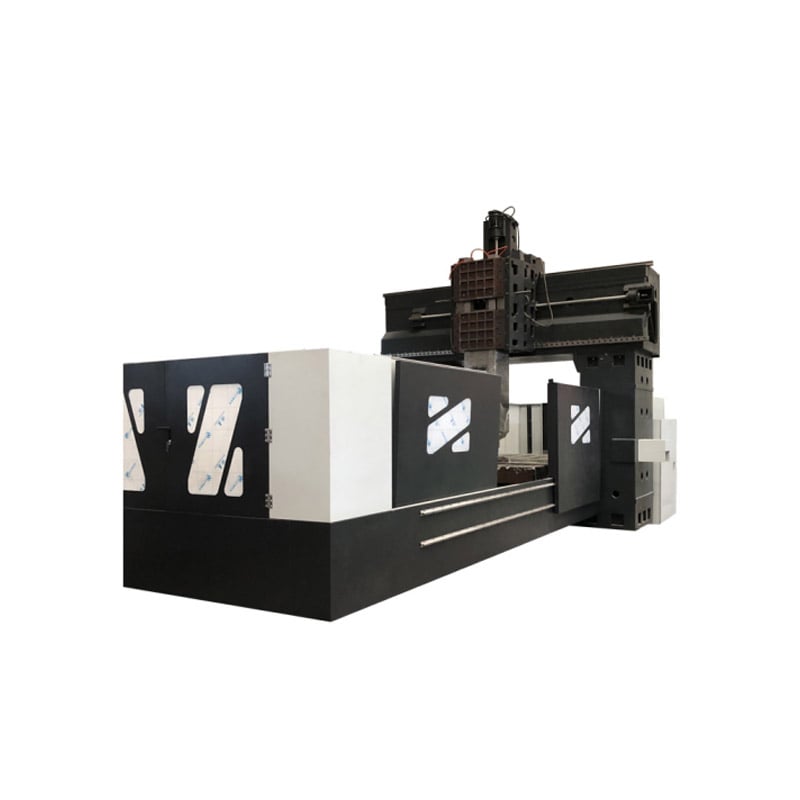

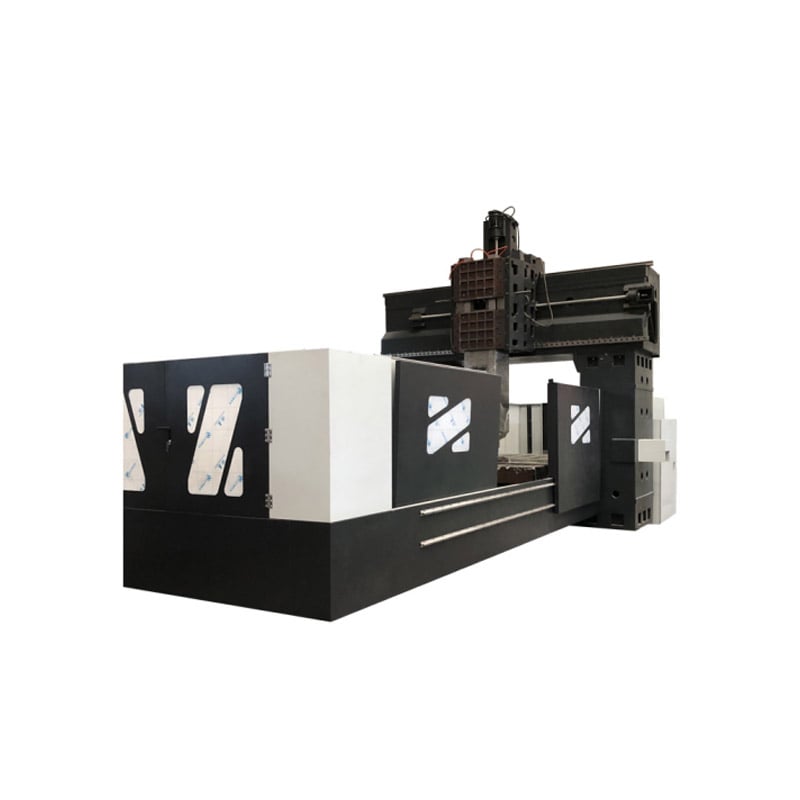

cnc milling machine 4 axis GMC3035 cnc gantry milling machine

The overall structure of the gantry metal cnc milling machine is composed of a gantry. The gantry consists of double columns, beams, connecting beams, top beams, top covers and milling head rams to form a rigid structure. The beams move up and down along the column guide rails.

The beam is equipped with a vertical high-power multi-function ram-type boring and milling head, the boring and milling head sliding plate moves along the beam guide rail and moves up and down, and the gantry structure moves longitudinally along the bed.

Product Description

cnc milling machine 4 axis GMC3035 cnc gantry milling machine

cnc gantry milling machine is a high-precision and necessary heavy machine for modern workpiece processing.

CNC Gantry Machining Center is referred to as CNC machine tool. It integrates computing technology, automatic control technology, sensor measurement technology, and network communication technology. It is a typical mechatronic product.

Video

Features:

1.Excellent in movement and cutting

2.Perfect for mold and dies in the automotive industry and large workpieces in the aerospace industry

3. Has sufficient static and dynamic rigidity and good precision retention.

4. Strong transmission rigidity, stable and reliable precision.

5. Small motion inertia and fast response

Video

Application field

Gantry type machine center has a wide range of uses, such as the processing of various complex plane, curved surfaces and shell parts, the milling of various cams, molds, connecting rods, blades, propellers, boxes and other parts, as well as drilling, expanding, Facing, reaming, tapping, boring and other processing items.

Gantry Machining Center should use cnc gantry milling machine for machining box, cavity, mold and other parts, and fix one tool for long-term milling.

Video

| Item | Unit | Specs | |

|---|---|---|---|

| Structure type | Fixed beam gantry type | Resin sand casting | |

| Gantry width | mm | 1280 | |

| Worktable | Worktable load | KG | 2500 |

| Worktable size | mm | 3000*3500 | |

| T-slot width | mm | 18 | |

| X.Y.Z Axis | Travel | mm | 3000*3500*450 |

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle | Spindle power | KW | 7.5 |

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H | m | 4.*2.3*2.6~2.9 |

| Weight | T | 13 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More