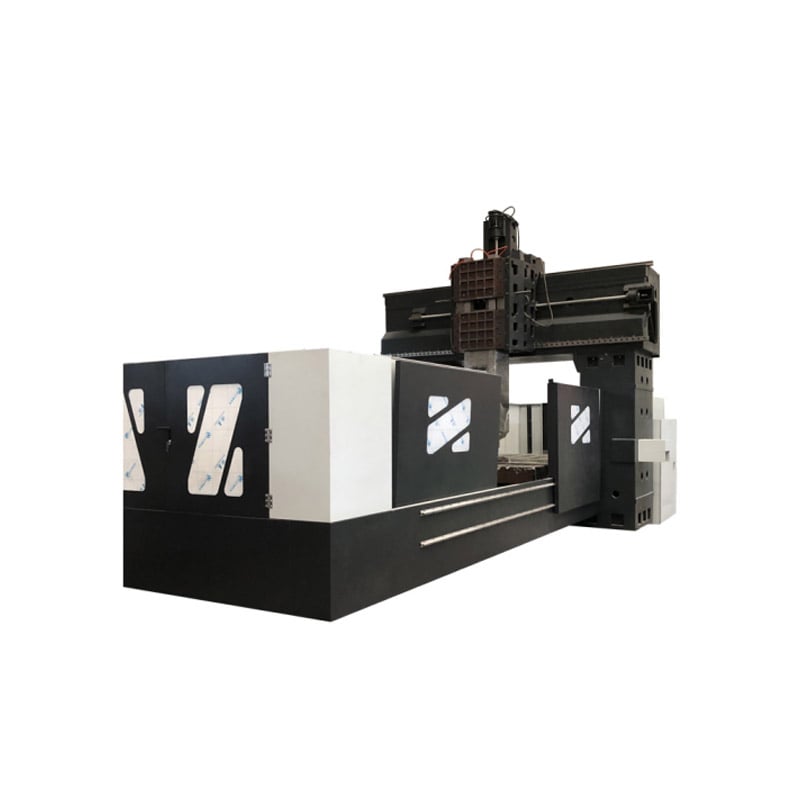

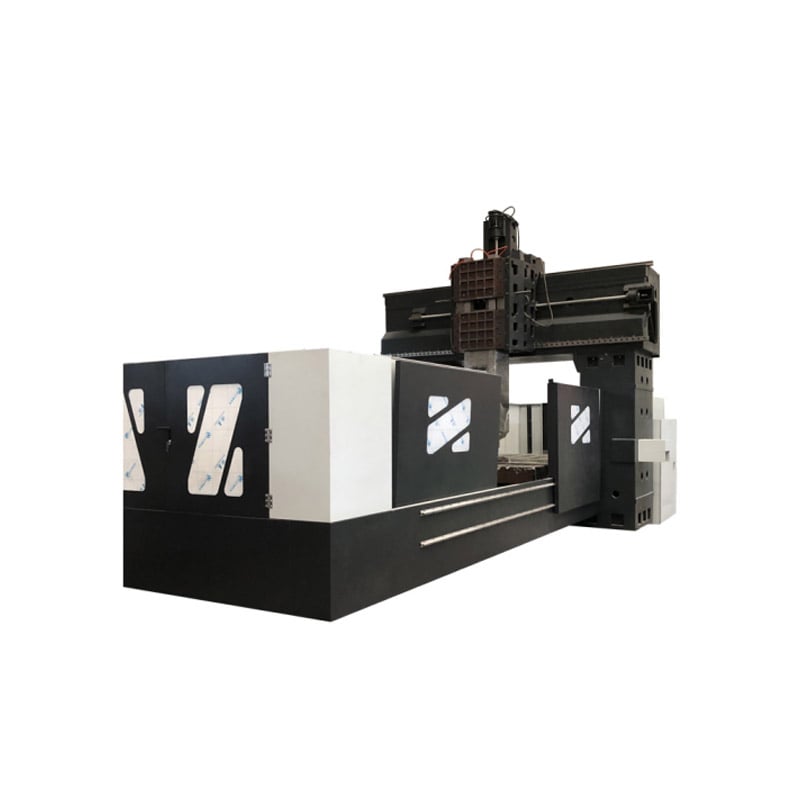

CNC Gantry Machining Center GMC3040 cnc 5 axis milling machine

CNC gantry milling machine is mainly composed of bed, milling head, longitudinal table, transverse saddle, lifting table, electrical control system and so on. It can complete basic milling, boring, drilling, tapping and automatic work cycles, and can process various complex cams, templates and mold parts.

Product Description

CNC Gantry Machining Center GMC3040 cnc 5 axis milling machine

The gantry type machine center base has large tonnage, firm structure, and high rigidity of machining accuracy.

The Gantry Machining Center is easy to operate, simple in structure and comprehensive in performance, making it the 5 Axis Gantry Milling Machine for a wide range of applications. It is commonly used in the milling of large and medium-sized ferrous and non-ferrous metals in various industries.

Video

CNC Gantry Machining Center Structural Features:

1. The bed base, worktable, gantry, carriage and headstock of the gantry metal cnc milling machine are all made of high-strength cast iron.

2.5 Axis Gantry Milling Machine machine tool guides use high-precision linear rolling guides, which have the characteristics of small friction coefficient, no creep at low speed, and quick start at high speed.

3. The gantry type machine center CNC system realizes three-axis linkage, which can complete the milling of straight lines, oblique lines, and curved contours. The driving motors are all AC servo motors.

Video

How cnc gantry milling machine works

The transmission system and machine tool structure of CNC Gantry Machining Center generally have high rigidity and thermal stability, and high manufacturing precision. The automatic processing method of gantry metal cnc milling machine can avoid errors caused by human factors of the operator. Therefore, machining The same batch of parts has good dimensional consistency, high precision, and very stable processing quality.

5 Axis Gantry Milling Machine processes parts automatically according to the pre-programmed programs. The operator usually does not need to perform heavy repetitive manual operations except for operating the panel, loading and unloading workpieces, intermediate measurements of key processes and observing the operation of the machine Intensity and tension are greatly reduced.

The gantry type machine center bed is equipped with X-axis guide rails, and the Gantry Machining Center table is fastened across the bed. A gantry frame is arranged on a movable spanning frame above the worktable, and the gantry frame also includes: a gantry frame carriage, and the gantry frame carriage is movably clamped on the X-axis guide rail. The Z-axis guide rail is installed on the gantry. The cross beam is equipped with a Z-axis carriage, the cross beam is movably clamped on the Z-axis guide rail through the Z-axis carriage, and the Y-axis guide rail is also installed on the cross beam.

Milling device, cnc drilling and milling machine The milling device is movably installed on the Y-axis guide rail, so that the gantry can perform three-dimensional space milling processing of X, Y, and Z axes under the control of the numerical control circuit control system. CNC milling machine has high-precision milling, drilling, boring, cutting and other operations.

Video

| Item | Unit | Specs | |

|---|---|---|---|

| Structure type | Fixed beam gantry type | Resin sand casting | |

| Gantry width | mm | 1280 | |

| Worktable | Worktable load | KG | 2500 |

| Worktable size | mm | 3000*4000 | |

| T-slot width | mm | 18 | |

| X.Y.Z Axis | Travel | mm | 3000*4000*450 |

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle | Spindle power | KW | 7.5 |

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H | m | 4*2.6*2.6~2.9 |

| Weight | T | 15 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More