CNC gantry milling machine GMC4040 cnc 5 axis milling machine

Product Description

CNC gantry milling machine GMC4040 cnc 5 axis milling machine

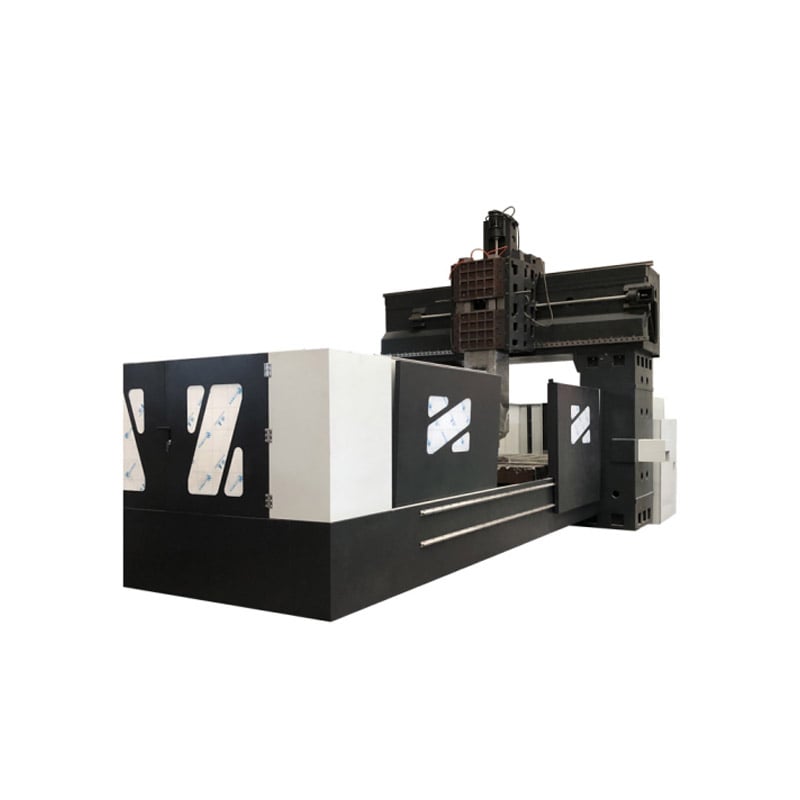

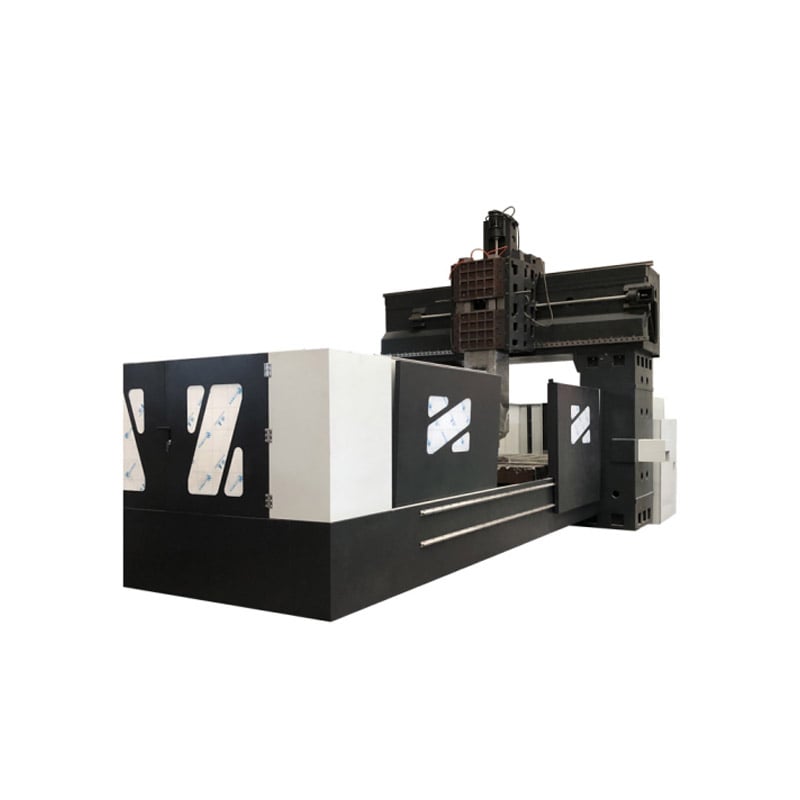

The cnc gantry milling machine is used to replace the large vertical machining center. The CNC Gantry Machining Center has a large work surface and machining area, which is ideal for the production of large workpieces and molds.

The gantry metal cnc milling machine has undergone precise analysis and excellent machine structure design to enhance the design of beams and bases. The efficiency and precision of the 5 Axis Gantry Milling Machine can help you get the job done.

Video

Main features of cnc gantry milling machine:

1. High flexibility and process compounding:

CNC Gantry Machining Center has the characteristics of high flexibility and complex process.

The so-called "flexibility" is flexible, versatile and flexible, and can adapt to automatic machine tools for processing workpieces of different shapes. The development of 5 Axis Gantry Milling Machine has blurred the concept of roughing and finishing processes, breaking the traditional process boundaries and separate processing process rules, which can maximize the efficiency of equipment utilization.

Gantry metal cnc milling machine can generally complete drilling, boring, reaming, plane milling, bevel milling, slot milling, surface milling, tapping and other processing. Moreover, in general, the required machining operations can be completed in one clamping.

2. High machining accuracy:

At present, the pulse equivalent of the numerical control device is generally 0.001mm, and the high-precision numerical control system can reach 0.0001mm. The gantry type machine center can generally ensure the machining accuracy of the workpiece. In addition, the numerical control machining can avoid the error of manual operation, and a batch of processing workpieces can be used. The uniformity of the size is relatively good, and the software can also be used for precision correction and compensation, which greatly improves the product quality.

3. High production efficiency:

The time required for part processing includes the maneuver time and the auxiliary time amount.

Gantry Machining Center can effectively reduce this part of the time, so the processing productivity is much higher than that of ordinary milling machines. The good structural rigidity allows the CNC gantry milling machine to perform powerful cutting with a large amount of cutting, which effectively saves the maneuvering time. The rapid movement and positioning of the moving parts of the cnc drilling and milling machine adopts acceleration and deceleration measures, so a high idle travel speed is selected, and the time consumed in fast forward, fast backward and positioning is much less than that of ordinary milling machines.

The spindle speed and feed of the CNC milling machine are infinitely variable, so it is beneficial to choose the best cutting amount.

4. Reduce the labor intensity of the operator:

cnc 5 axis milling machine automatically completes the processing of parts according to the pre-programmed program. Except for operating the keyboard, loading and unloading workpieces, intermediate measurement and observation of the machine tool movement, heavy and repetitive manual operations are not required, which can greatly reduce labor. strength.

Because the big cnc milling machine has the above advantages, the cnc milling machine 4 axis has become the main equipment in the machinery manufacturing industry.

However, the programming operation of the Double Column Milling Machine is more complicated and requires higher quality of programmers. Otherwise, it is difficult to play the role of CNC milling machine.

Video

Application of gantry type machine center

Gantry Machining Center is a large machine tool specially designed for machining large parts.

cnc drilling and milling machine is mainly used in heavy industry, such as aircraft, automobiles, ships and other heavy industries.

All in all, CNC milling machine is a large-scale machine tool designed for processing large and complex parts, which is suitable for various industries, especially the large-scale parts industry.

Video

| Item | Unit | Specs | |

|---|---|---|---|

| Structure type | Fixed beam gantry type | Resin sand casting | |

| Gantry width | mm | 1280 | |

| Worktable | Worktable load | KG | 2500 |

| Worktable size | mm | 4000*4000 | |

| T-slot width | mm | 18 | |

| X.Y.Z Axis | Travel | mm | 4000*4000*450 |

| X.Y axis fast moving speed(no load) | mm/min | 8000-12000 | |

| Z axi fast moving speed | mm/min | 7000-10000 | |

| Fastest processing speed | mm/min | 6000 | |

| Positioning accuracy | mm/mm | 0.02/300 | |

| Re-positioning Accuracy | mm | 0.02 | |

| Spindle | Spindle power | KW | 7.5 |

| Spindle motor speed | r/min | 0-8000 | |

| Spindle speed | r/min | 100-8000 | |

| Spindle to table distance(about) | mm-mm | 120-570 | |

| Dimensions | L*W*H | m | 4*2.3*2.6~2.9 |

| Weight | T | 18 | |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More