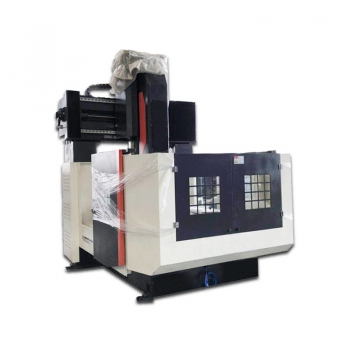

CNC gantry milling machine GMC1012 gantry type machine center

cnc gantry milling machine is a kind of mechanical equipment that can process large workpieces on the plane and slope. It is suitable for batch and mass production. It has a portal frame and a long horizontal bed, with high machining accuracy and high production efficiency.

Among them, on the CNC Gantry Machining Center, some special parts can also be processed in space or curved surface, which can be described as a lot of applications.

Product Description

CNC gantry milling machine GMC1012 gantry type machine center

cnc gantry milling machine is a processing technology that uses a milling machine with a portal frame and a horizontal long bed to process the plane, inclined plane, space curved surface and some special mechanical parts of large workpieces.

CNC Gantry Machining Center is a machining process that can use multiple milling cutters to machine the surface of the workpiece at the same time, and the machining accuracy and efficiency are relatively high.

Video

Technical advantages of gantry metal cnc milling machine?

1. Gantry type machine center has very good carrying capacity;

2. The guide rail wears less, and the Gantry Machining Center has high precision retention;

3. The moving speed and acceleration are stable;

4. Servo motion performance is high;

5.cnc drilling and milling machine has high processing precision.

Video

The application of cnc gantry milling machine is more and more extensive, and it mainly has the following features.

1. Through linear and circular interpolation, CNC Gantry Machining Center can realize continuous contour control with motion trajectory, and process plane contour work composed of two geometric elements of straight line and circular arc.

2. Point control function, using this function, the gantry metal cnc milling machine can perform drilling, reaming, reaming and boring that only need point control.

3. The gantry type machine center can automatically change the height of the cutting plane by using the tool edge length compensation function. At the same time, it can reduce the accuracy requirements of the tool length and dimension during manufacturing and repair, and can also compensate for the axial tool setting error.

4. Gantry Machining Center compensates for the dimensional accuracy error of milling cutters by changing the amount of tool radius compensation, and expands the selection range of tool diameters and the allowable error of tool rework and sharpening.

Video

| Main Technical Parameters of The Machine Tool | ||

| Item | Name | ALGMC1012 |

| Gantry width(mm) | 1080 | |

| WORKTABLE | Worktable load (KG) | 2000 |

| Worktable size (mm) | 1000*1200 | |

| T-slot width | 18mm | |

| X.Y.Z AXIS | Travel (mm) | 1000*1200*450 |

| Y axis screw | 4010 | |

| X axis screw | 3210 | |

| Z axis screw | 3205 | |

| X.Y axis fast moving speed(no load)( mm/min) | 10000 | |

| Z axis fast moving speed(mm/min) | 7000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | -3.33333E-05 | |

| Re-positioning accuracy(mm) | -0.01 | |

| Spindle motor speed(r/min) | 500-8000 | |

| Nasal end to table distance (about)(mm) | 120-570 | |

| DIMENSIONS | L*W*H(m)(About) | 3.4*2.3*2.6~2.9(Highest) |

| MACHINE WEIGHT | (About)(T) | 7 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More