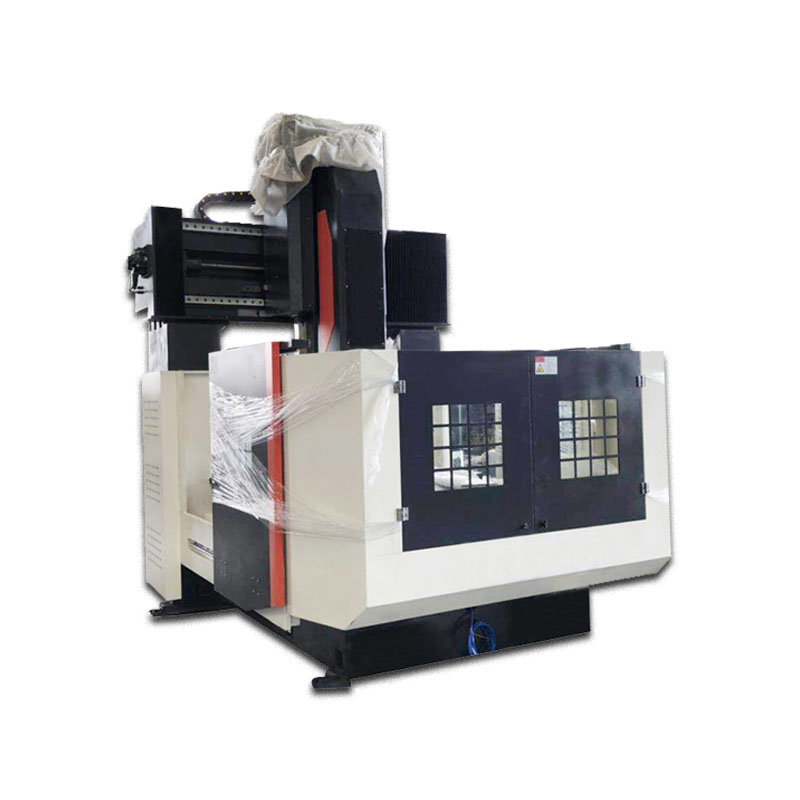

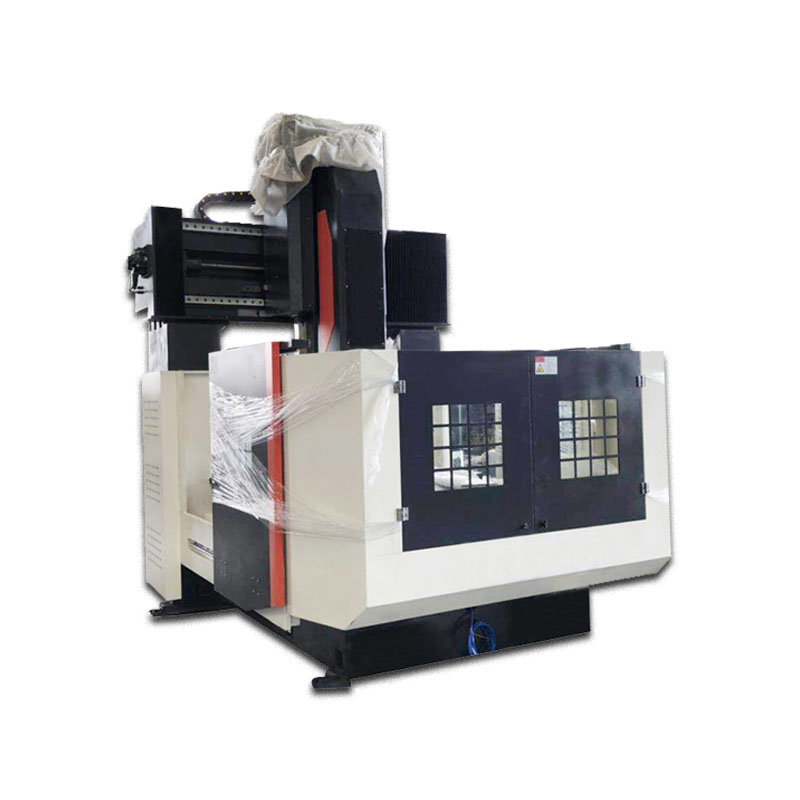

CNC gantry milling machine GMC1090 big cnc milling machine

Product Description

CNC gantry milling machine GMC1090 big cnc milling machine

cnc gantry milling machine, referred to as gantry milling machine, is a milling machine with a gantry frame and a long horizontal bed.

CNC Gantry Machining Center can use multiple milling cutters to machine the surface at the same time, with high machining accuracy and production efficiency.

5 Axis Gantry Milling Machine is suitable for machining flat and inclined surfaces of large workpieces in batch and mass production. CNC gantry milling machines can also process space curved surfaces and some special parts.

Video

Features of gantry type machine center:

1. The front and rear, up and down driving programs of the grinding head: Gantry Machining Center adopts sliding guide rails, the surface is quenched and precision ground, which is suitable for heavy cutting. The top and bottom of the horizontal axis and the top and bottom of the vertical axis are equipped with precision ball screws and servo water-cooled drive system, which has large torque and ensures the accuracy of feed.

2. Design of automatic lubrication system: CNC Gantry Machining Center can automatically and completely lubricate the whole machine. cnc gantry milling machine is designed to recycle and filter waste oil for circulating lubrication, which is not only environmentally friendly, but also saves lubricating oil. cnc drilling and milling machine adopts circulating type central lubrication device.

Video

Application industry of gantry metal cnc milling machine

The structural characteristics of typical parts in the aviation industry are that they use a large number of integral thin-walled structures and have complex shapes. In order to increase the maneuverability of the aircraft, increase the payload and range, and reduce the cost, lightweight design and extensive use of new lightweight materials.

Now a large number of aluminum alloys, superalloys, titanium alloys, high-strength steels, composite materials, engineering ceramics, etc. are used.

Thin-walled parts and honeycomb parts with complex structures have complex shapes, many holes, holes, grooves, ribs, etc., and the process rigidity is poor.

According to the structural characteristics and processing requirements of machining parts in the aviation industry, the 5 Axis Gantry Milling Machine is required to have sufficient rigidity, simple operation, clear man-machine interface to reduce the impact on the machining accuracy of the corners, and online measurement and simulation functions.

Video

| Item | Name | GMC1090 |

|---|---|---|

| Structure type | Fixed beam gantry structure | |

| Gantry width(mm) | 980 | |

| Worktable | Worktable load (KG) | 2000 |

| Worktable size (mm) | 900*1000 | |

| T-slot width | 18mm | |

| X.Y.Z Axis | Travel (mm) | 900*1000*450(optional) |

| X.Y axis fast moving speed(no load)( mm/min) | 8000-15000 | |

| Z axis fast moving speed(mm/min) | 7000-10000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 | |

| Spindle | Spindle motor power | 7.5KW Servo |

| Spindle motor speed(r/min) | 0-8000 | |

| Dimensions | L*W*H(m)(About) | 2.9*2.3*2.8 |

| Machine weight | (About)(T) | 6 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More