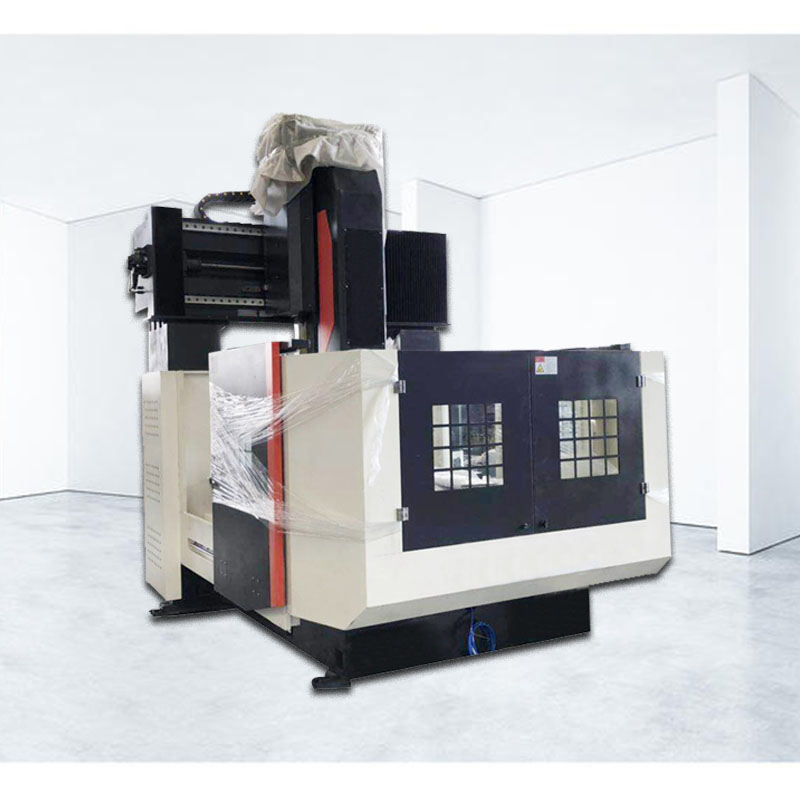

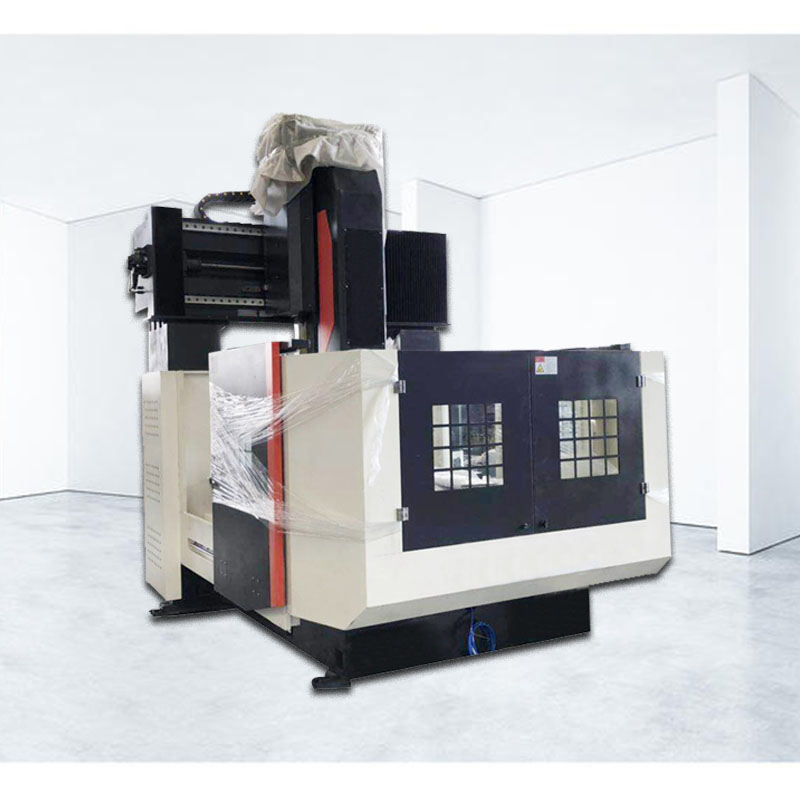

CNC Gantry Milling Machine Center GMC1311

Product Description

CNC Gantry Milling Machine Center GMC1311 CNC Gantry Machining Center

Gantry milling machine, referred to as gantry milling machine, is a milling machine with a portal frame and a long horizontal bed.

The CNC Gantry Milling Machine Center can use multiple milling cutters to machine the surface at the same time, and the machining accuracy and production efficiency are relatively high. It is suitable for machining the flat and inclined surfaces of large workpieces in batch and mass production.

CNC Gantry Milling Machine Center GMC1311 can also process space curved surfaces and some special parts.

CNC Gantry Milling Machine Center GMC1311 Specifications:

CNC Gantry Milling Machine Center GMC1311 Specifications:

| Item | Name | ALGMC1311 |

| Structure type | Gantry width(mm) | 1180 |

| Worktable | Worktable load (KG) | 2000 |

| Worktable size (mm) | 1100*1300 | |

| T-slot width | 18mm | |

| X.Y.Z Axis | Travel (mm) | 1100*1300*450 |

| X.Y axis fast moving speed(no load)( mm/min) | 8000-12000 | |

| Z axis fast moving speed(mm/min) | 7000-10000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 | |

| Spindle | Spindle motor power | 7.5KW |

| Spindle motor speed(r/min) | 0-8000 | |

| Spindle form | Mechanical spindle | |

| Spindle model brand | BT40 | |

| Nasal end to table distance (about)(mm) | 120-570 |

Learn more about the advantages of GMC1311 CNC Gantry Machining Center:

1. Good processing adaptability;

When the machining object of CNC Gantry Milling Machine Center GMC1311 is changed, it only needs to re-compile and input new programs to meet the machining process requirements of the machining object, and the machining transformation can be realized quickly.

2. Conducive to the modernization of production management;

CNC Gantry Milling Machine processing can accurately calculate the processing time of parts, and simplifies the management of inspection jigs and semi-finished products, which is conducive to the modernization of production management.

3. High processing productivity;

The time required for parts processing includes two parts: maneuvering time and auxiliary time. The gantry milling machine can reduce these two parts of time, thereby improving the processing rate.

4. High machining accuracy;

5. Good economic benefits;

6. The processing labor intensity is low;

Production-type CNC Gantry Milling Machines generally have better safety protection and automatic chip removal, automatic cooling, automatic lubrication and other device operators. The labor conditions have also been improved accordingly.

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More