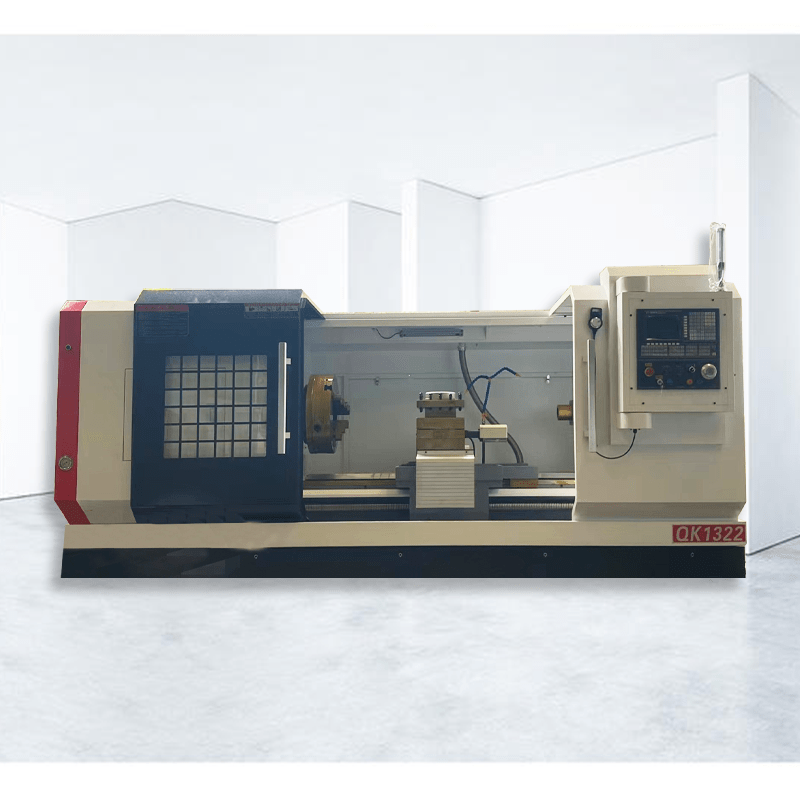

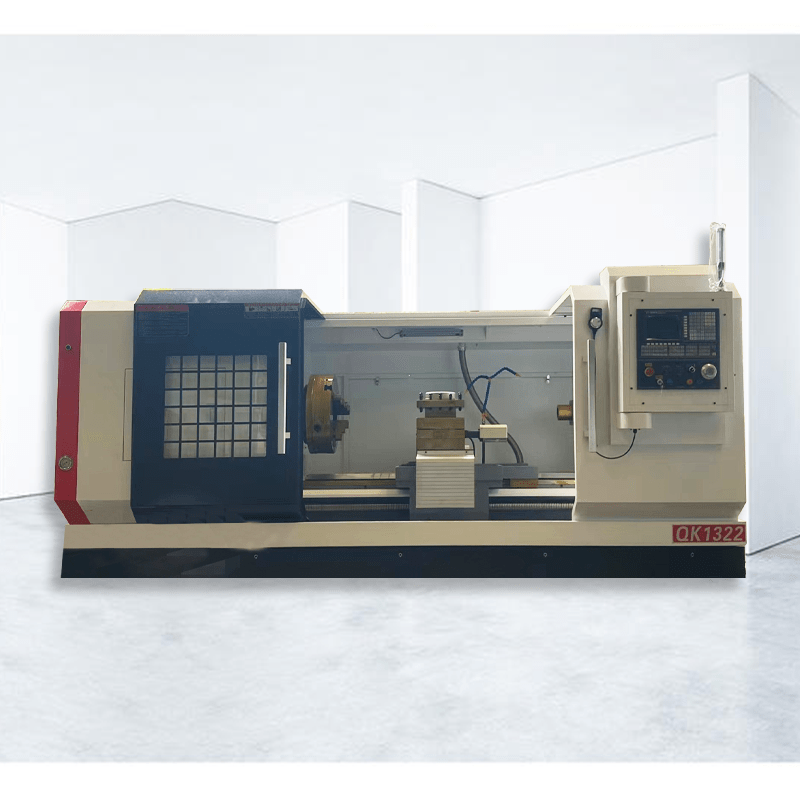

CNC pipe threading lathe ALQK1322 CNC Oil Lathe

CNC pipe thread lathe is a horizontal lathe designed for turning large diameter pipe fittings

CNC lathe pipe thread lathe machine is widely used in mechanical processing operations in machinery manufacturing, petroleum, chemical, coal, geological exploration, urban water supply and drainage and other industries.

Product Description

The cnc lathe pipe thread lathe machine spindle box adopts a powerful external circulation cooling and lubrication system, ball screw direct drive, screw prestressed tension structure, super-large specification four-station CNC electric tool holder.

CNC pipe threading lathe is widely used in the processing of drill pipes, joints, casings and other parts in the petroleum industry. It can also be applied to the processing of various pipe threads in chemical, coal, geological and other industries.

Features:

1. CNC turning machine can process internal and external straight pipe thread and tapered pipe thread with pipe thread diameter up to 190mm. The lathe is equipped with a taper device that can process a taper of 1:5.

2. CNC pipe threading lathe can turn metric and inch threads without changing gears. There is a shedding worm in the slide box, which can automatically protect the integrity of the lathe mechanism.

3. The guide rail of cnc lathe pipe thread lathe machine has been quenched and wear-resistant and finished. It has high power and is capable of heavy-duty and powerful cutting.

4. The CNC Oil pipe lathe ground center frame can be moved freely according to the user's needs. The center frame is equipped with a long pipe clamping adjustment mechanism, which greatly reduces the labor intensity.

5. There are four-jaw chucks at the front and rear of the CNC Oil Lathe head box, which are suitable for the desired clamping of long and short pipes.

Application of metal lathe:

CNC turning machine is widely used in mechanical processing operations in machinery manufacturing, petroleum, chemical, coal, geological exploration, urban water supply and drainage and other industries.

Video

Product Specifications

|

Content

|

Unit | ALQK1322 |

|

Maximum turning diameter of bed

|

mm | Φ630 |

| Maximum turning diameter on the skateboard | mm | Φ330 |

|

Maximum processing length

|

mm | 1500 |

| Maximum machining diameter | mm | Φ630 |

| Maximum bar diameter | mm | Φ330 |

| Spindle through hole diameter | mm | Φ220 |

| Sleeve diameter/stroke | mm | Φ100/250 |

| Machine weight | kg | 4200 |

| Machine tool dimensions | mm | 3750X1830X1900 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More