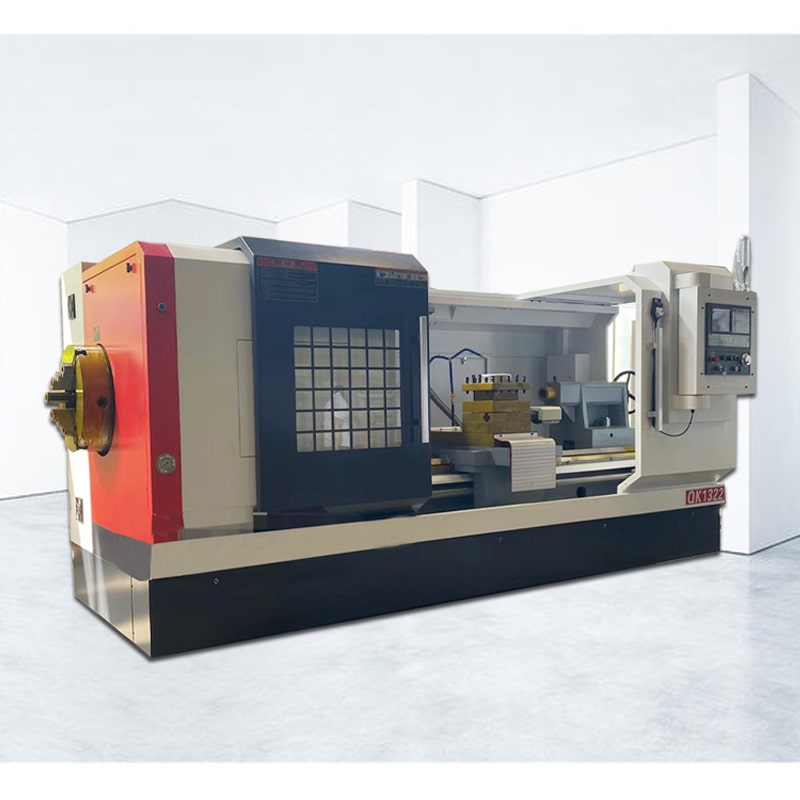

CNC Oil pipe lathe ALQK1332 CNC pipe thread lathe

Product Description

CNC pipe threading lathe is mainly used to process internal and external threads of pipeline tools, and at the same time has the function of CNC lathe, which can process the outer circle, inner hole and end surface of workpieces such as shafts and disks;

cnc lathe pipe thread lathe machine is widely used in the processing and repair of drill pipes, joints, casings and other parts in some industries, and it is also used in thread processing of various pipes and drill pipes in chemical, coal, geological and other industries.

Video

Features:

1. The bed of CNC pipe threading lathe is an original three-layer wall structure, and the bed is quenched and precision ground by super-audio frequency, which effectively guarantees the accuracy and service life of the machine tool.

2. The integral gearbox type spindle unit of cnc lathe pipe thread lathe machine has two-speed frequency conversion and stepless speed change within the gear, which not only meets the requirements of fine thread turning, but also achieves high-efficiency cutting.

3. The CNC turning machine has an integral gearbox-type spindle unit, a spindle servo structure frequency conversion motor, and two-stage mechanical speed regulation. The wide range of speed adjustment not only meets the requirements of fine thread turning, but also achieves high-efficiency cutting. The application of hardened precision ground gears and high-quality bearings ensures low noise and good sound quality of the machine tool. The spindle box adopts a powerful external circulation cooling and lubrication system, which not only reduces the temperature rise of the spindle, but also effectively maintains the cleanliness and lubrication of the spindle box.

Application industry:

CNC pipe threading lathe can be used in the processing of oil pipes, casings and drill pipes in petroleum, chemical and metallurgical industries. It is mainly used to process internal and external pipe threads. It is automatically controlled by the numerical control system and can accurately process various internal and external threads. The inner hole and the end face and the conical surface are processed.

Product Specifications

|

Content

|

Unit | ALQK1322 |

|

Maximum turning diameter of bed

|

mm | Φ630 |

| Maximum turning diameter on the skateboard | mm | Φ330 |

| Maximum processing length | mm | 1500 |

| Maximum machining diameter | mm | Φ630 |

| Maximum bar diameter | mm | Φ330 |

| Spindle through hole diameter | mm | Φ220 |

| Sleeve diameter/stroke | mm | Φ100/250 |

| Machine weight | kg | 4200 |

| Machine tool dimensions | mm | 3750X1830X1900 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More