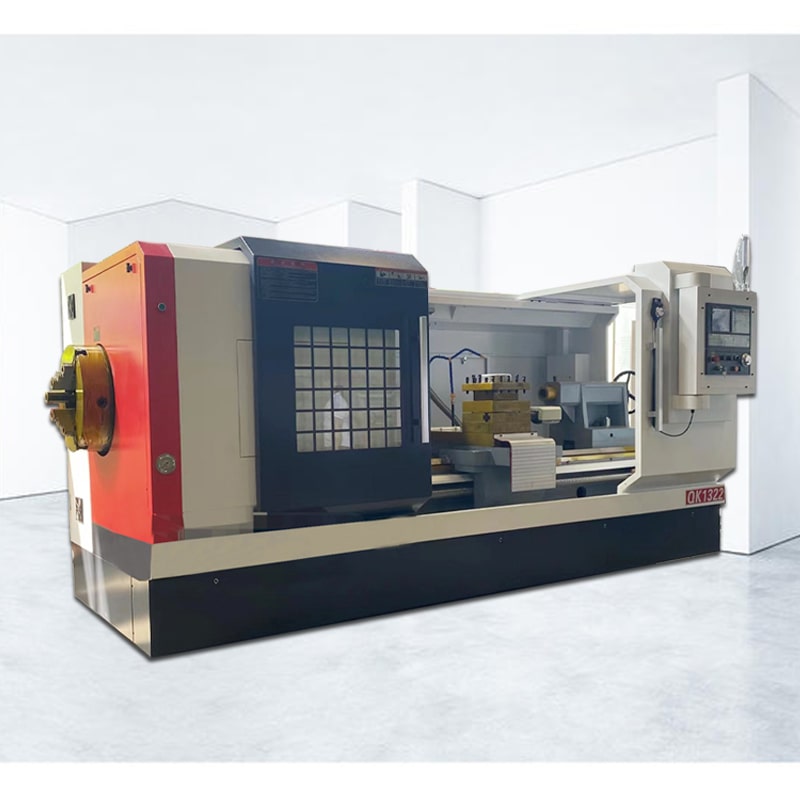

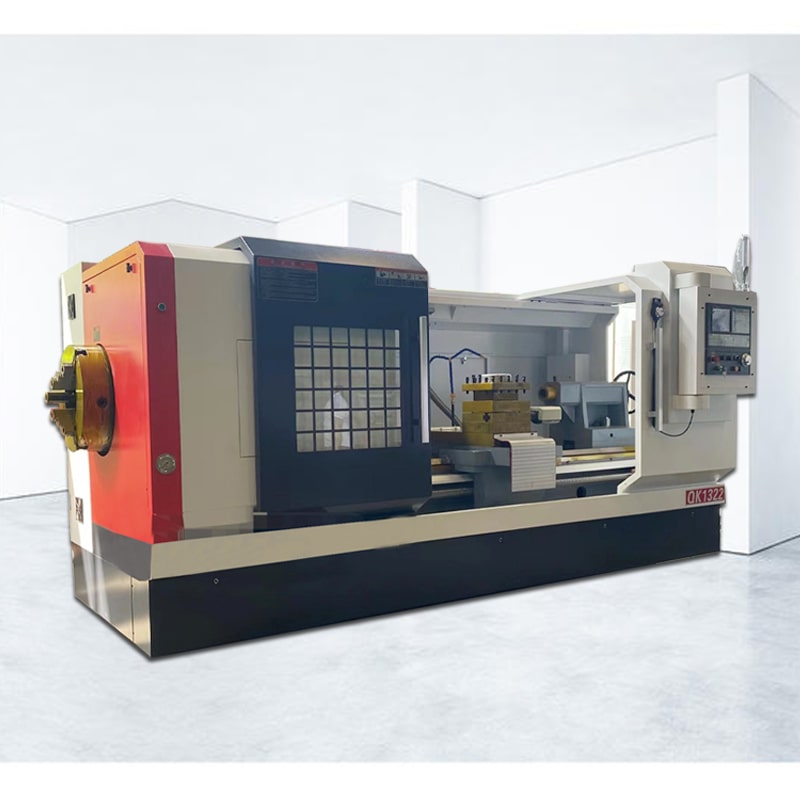

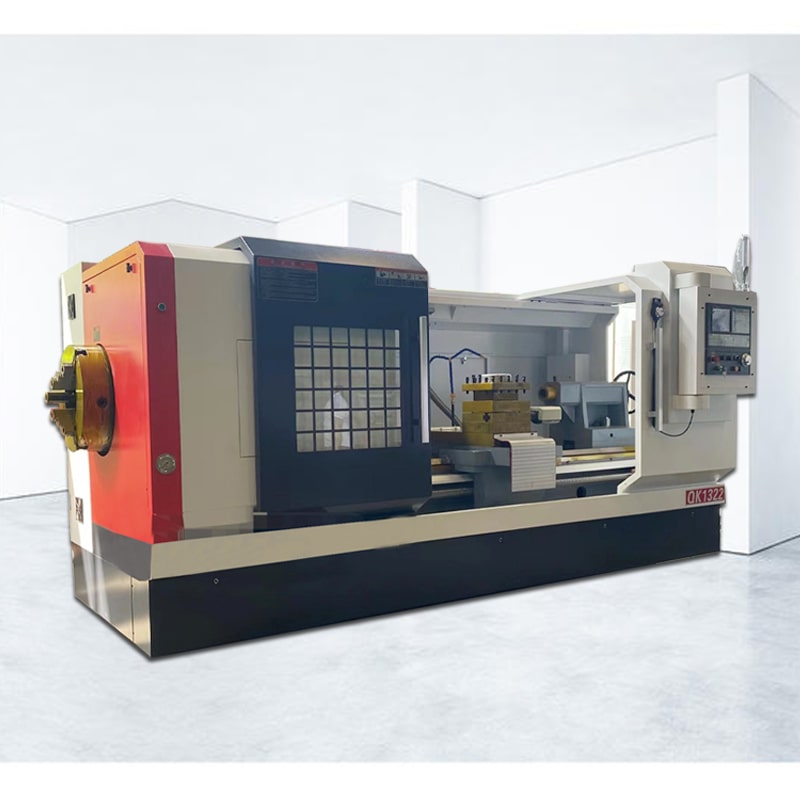

CNC pipe thread lathe ALQK1332 CNC lathe pipe thread lathe machine

Product Description

The CNC pipe thread lathe ALQK1332 is used for processing and clamping the pipe, feeding the cutting tool, cutting, and automatically discharging the processed pipe. The processing process is controlled by the numerical control system, which can realize high-precision and high-efficiency pipe processing and greatly improve production efficiency. In the field of pipeline processing, the application of CNC pipe thread lathes has also greatly improved the processing accuracy and quality of pipes, providing more reliable pipeline systems for all walks of life.

Video

Product Specifications

Features:

1. CNC pipe threading lathe adopts computer control system, which can realize high-precision position control and machining accuracy, and meet the requirements of precision machining.

2. The operation of CNC Oil pipe lathe has a high degree of automation, which can realize high-efficiency processing and greatly improve processing efficiency.

3. CNC pipe threading lathe can perform various operations such as thread processing and end face processing, and has strong versatility.

4. CNC Oil pipe lathe adopts high-quality mechanical transmission system, which has good stability and more stable processing effect.

Application industry:

CNC pipe thread lathe ALQK1332 is widely used in manufacturing industry, especially automobile, machinery, aviation and other industries. Its main application scenario is to process threads and end faces, which can meet the processing requirements of different industries for parts. CNC pipe thread lathes are also widely used in the field of pipeline processing, such as the processing of oil pipes, natural gas pipes, water pipes, etc., providing efficient and high-precision processing solutions for all walks of life.

Video

Product Specifications

|

Content

|

Unit | ALQK1322 |

| Maximum turning diameter of bed | mm | Φ630 |

| Maximum turning diameter on the skateboard | mm | Φ330 |

| Maximum processing length | mm | 1500 |

| Maximum machining diameter | mm | Φ630 |

| Maximum bar diameter | mm | Φ330 |

| Spindle through hole diameter | mm | Φ220 |

| Sleeve diameter/stroke | mm | Φ100/250 |

| Machine weight | kg | 4200 |

| Machine tool dimensions | mm | 3750X1830X1900 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More