VMC650 3 axis milling machine center

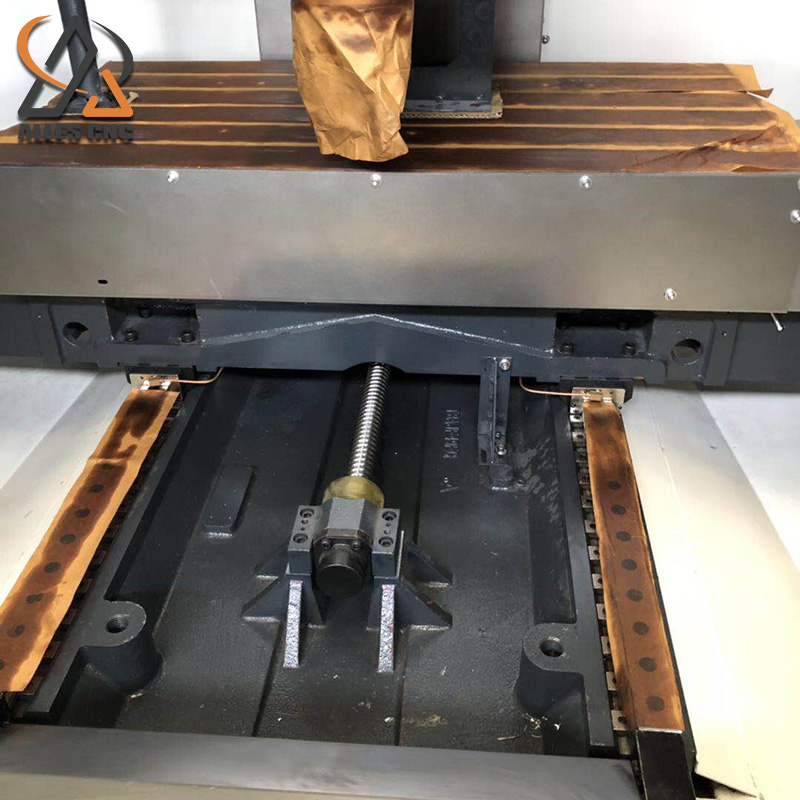

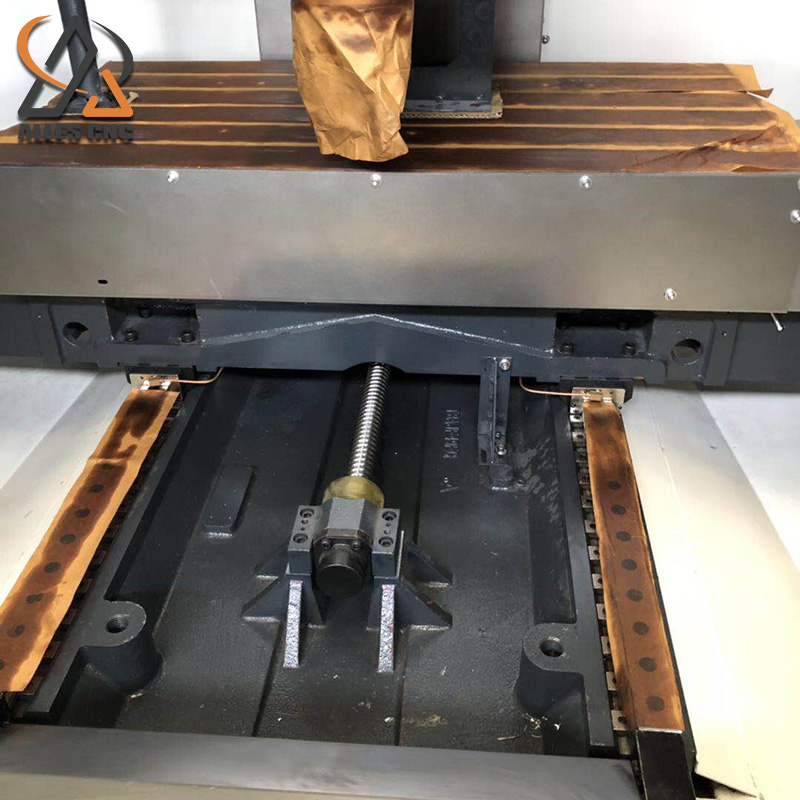

The VMC650 3 axis cnc machine is a bed-type vertical machining center. The large herringbone structure of the column is fixed, and the X/Y/Z three-axis servo motor is directly controlled. The processing efficiency is high, the running speed is fast, and the structure and external dimensions are compact and reasonable.

Product Description

VMC650 3 axis milling machine center

Product description:

VMC650 china cnc milling machine spindle drive is equipped with a servo motor, which has strong power, strong overload capacity and strong cutting ability. The machine tool can realize one-time clamping of various discs, plates, shells, cams, molds and other complex parts, and can complete various processes such as drilling, milling, boring, expanding, reaming, and rigid tapping.

Vertical machining center VMC650

Video:

| Model | ALVMC650C |

| Travel | |

| X axis | 600mm |

| Y axis | 500mm |

| Z axis | 500mm |

| Distance from spindle nose to table | 100-600mm |

| Distance from spindle center to column | 550mm |

| Worktable | |

| Worktable size | 800×500mm |

| Max. loading capacity | 400kg |

| T-slot | 5×18×90mm |

| Spindle | |

| Speed | 8000rpm |

| Taper | BT40 |

| Main motor power | 5.5Kw |

| Feed | |

| Rapid feed speed | 20m/min |

| Cutting feed speed | 10m/min |

| Positional accuracy | 0.016mm |

| Repeated positional accuracy | 0.006mm |

| X Y Z motor torque | 10/10/15Nm |

| Machine | |

| Weight | 3800 Kg |

| Overall dimensions(L×W×H) | 1900×2310×2300mm |

Product advantages:

1. The head group is a heavy box structure. Internal rib reinforcement, high rigidity.

2. The hydraulic mechanism is adopted for the spindle cutting method, and the spindle is evenly stressed during cutting, which prolongs the bearing life.

3. The electrical box adopts the internal isolation design, and the heat source part of the controller is separated. The front side uses a heat exchanger to dissipate heat to prevent external dust from entering the electrical box; the rear side uses a fan to dissipate heat for the fan hot plate.

Vertical machine center processing mold

Video:

Cnc machining center, cnc lathe online inspection

Video:

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More