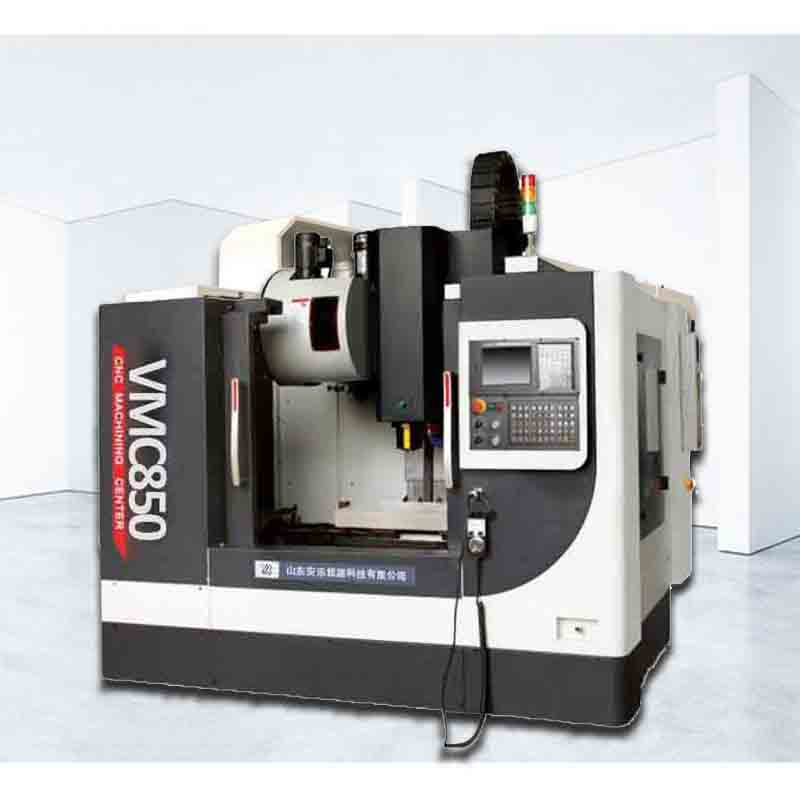

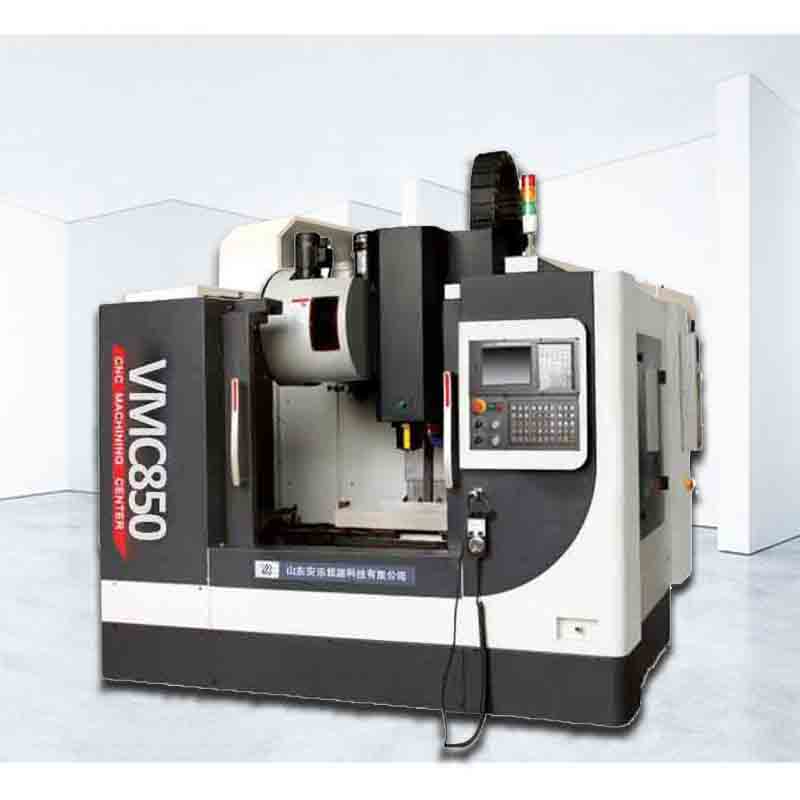

VMC850 4 axis cnc milling machine

VMC850 vertical machining center can be used in many fields such as machining and mold manufacturing. VMC850 cnc milling center has the characteristics of high precision and high efficiency, and is widely used in machining in aerospace, mold, automobile, chemical, petroleum, electronics and other industries.

Product Description

VMC850 4 axis cnc milling machine

Product description:

VMC850 3 axis metal milling machine is a vertical machining center suitable for machining and mold manufacturing. VMC850 cnc milling center can adapt to the processing requirements from roughing to finishing, and can complete various processes such as milling, drilling, tapping, and boring.

Video:

Product Specifications:

| Model | ALVMC850C |

| Travel | |

| X axis | 1000mm |

| Y axis | 500mm |

| Z axis | 500mm |

| Distance from spindle nose to table | 100-600mm |

| Distance from spindle center to column | 550mm |

| Worktable | |

| Worktable size | 1000×500mm |

| Max. loading capacity | 400kg |

| T-slot | 5×18×90mm |

| Spindle | |

| Speed | 8000rpm |

| Taper | BT40 |

| Main motor power | 5.5Kw |

| Feed | |

| Rapid feed speed | 20m/min |

| Cutting feed speed | 10m/min |

| Positional accuracy | 0.016mm |

| Repeated positional accuracy | 0.006mm |

| X Y Z motor torque | 10/10/15Nm |

| Machine | |

| Weight | 3800 Kg |

| Overall dimensions(L×W×H) | 1900×2310×2300mm |

Product advantages:

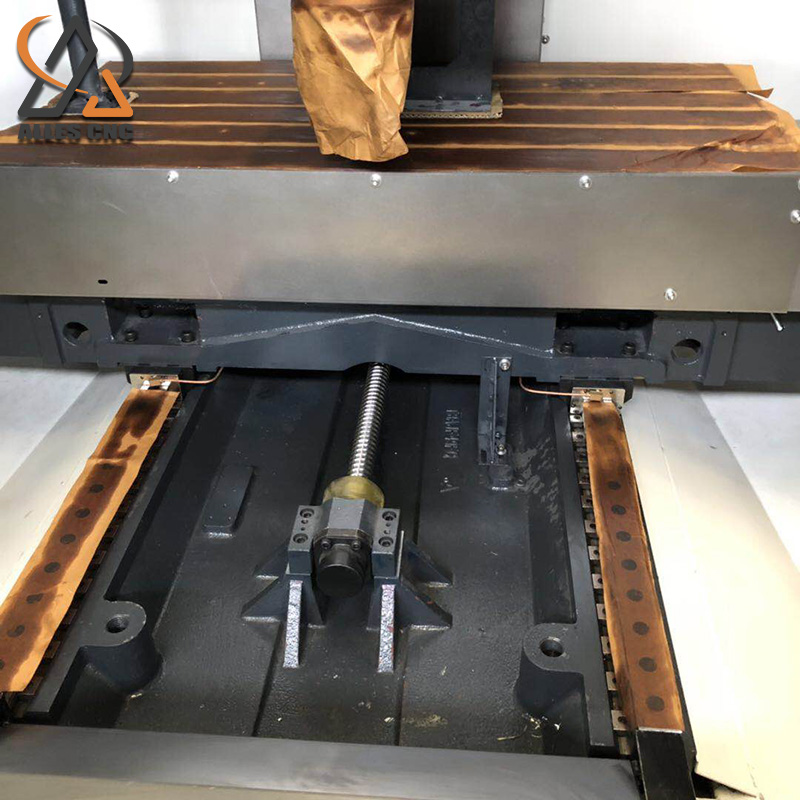

1. The main components are made of resin sand castings, which have good rigidity after multiple stress relief processes.

2. The guide rail is attached with a wear-resistant patch, which is finely ground by hand. With special guide seat design, the machine tool has strong load capacity and is suitable for high torque cutting.

3. The guide rail is quenched by high frequency and ground with high precision, which makes the hardness, precision and stability of the machine tool better.

4. High-torque AC servo motor and quick tool change system are equipped with precision spindle bearings, which can carry out strong cutting and high-speed machining, and the overall efficiency is higher.

Video:

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More