Milling cnc vertical machining center VMC cnc milling machine

Product Description

Milling cnc vertical machining center VMC cnc milling machine

A vertical machine center is commonly known as CNC vertical machine center. It is a type of manufacturing centers that can be used to produce complex products with pinpoint accuracy. The cutting tool or other tooling used in these centers is computer-controlled to manage the process of material removal and ensure accuracy during the process.

Milling cnc vertical machining center VMC cnc milling machine Specification:

Product Description :

A vertical machine center is commonly known as CNC vertical machine center. It is a type of manufacturing centers that can be used to produce complex products with pinpoint accuracy. The cutting tool or other tooling used in these centers is computer-controlled to manage the process of material removal and ensure accuracy during the process.

Milling cnc vertical machining center VMC cnc milling machine Specification:

| Model | ALVMC1160 |

| Travel | |

| X axis | 1100mm |

| Y axis | 600mm |

| Z axis | 600mm |

| Distance from spindle nose to table | 120-720mm |

| Distance from spindle center to column | 600mm |

| Worktable | |

| Worktable size | 1200×600mm |

| Max. loading capacity | 800kg |

| T-slot | 5×18×100mm |

| Spindle | |

| Speed | 8000rpm |

| Taper | BT40 |

| Main motor power | 11Kw |

| ATC | |

| Tools type | Disc type |

| Number of tools | 24 |

| Tool change time | 2.8s |

| Tool length max. | 250mm |

| Tool weight max. | 8kg |

| Machine | |

| Weight | 7300 Kg |

| Overall dimensions(L×W×H) | 3200×2450×2650mm |

Product Description :

VMC series vertical machining center inherits the advantages of strong rigidity, symmetrical struc-ture and strong stability of the foundation frame of the traditional vertical CNC milling machine,introduces the international advanced dynamic rigidity design concept, and optimizes the design of the moving parts.

Product Features:

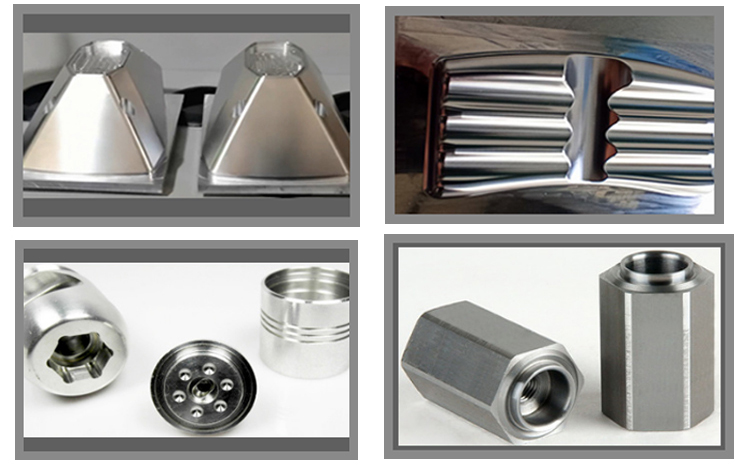

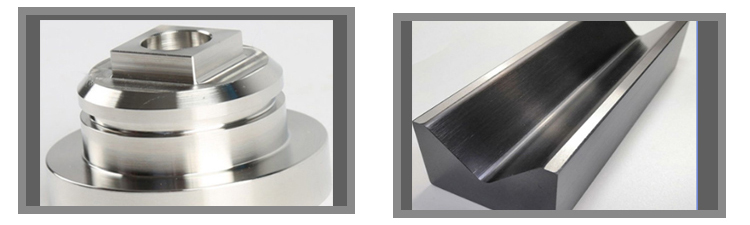

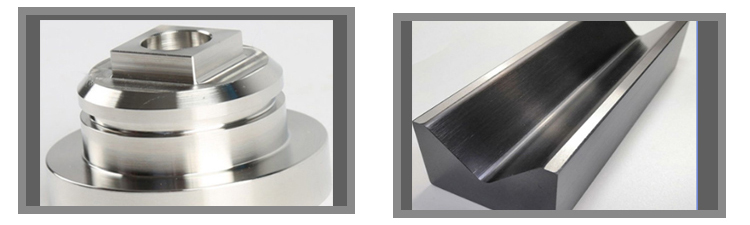

The machine tool adopts a new generation of vertical machining center with high precision, high speed and high rigidity developed by 3D computer-aided design and finite element analysis. The guide rail adopts three-line rail (or two-line one-hard) guide rails, and the maximum rapid speed can reach 48m / min, spindle speed 6000 to 15000 rpm optional positioning accuracy <4μm, repeated positioning <3μm; suitable for various mechanical processing fields such as mold, military industry, hardware, auto parts and so on.

What are vertical machining centers used for?

Vertical machining centers are used in various areas across the automotive, aerospace and aerospace industries.

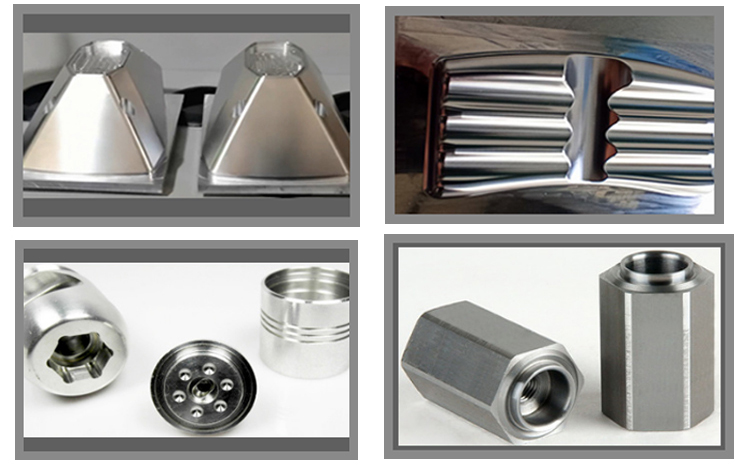

Vertical machining centers are used for a wide range of applications, including:

-precision screw machines in each axis

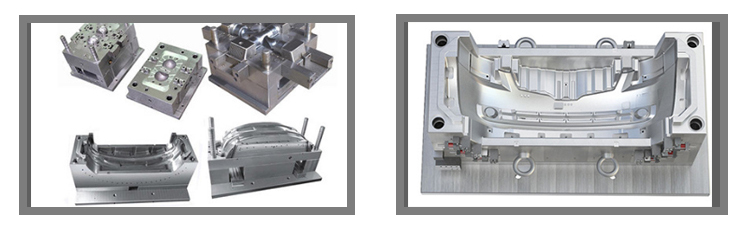

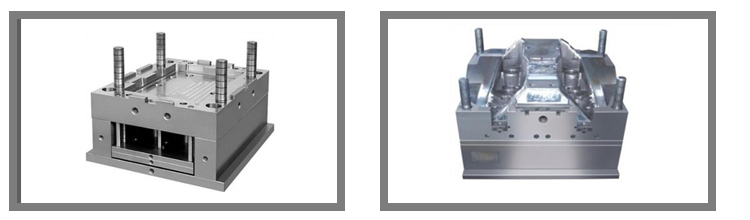

-tooling and fixtures for making molds

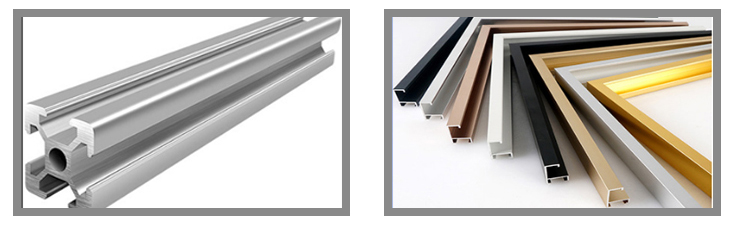

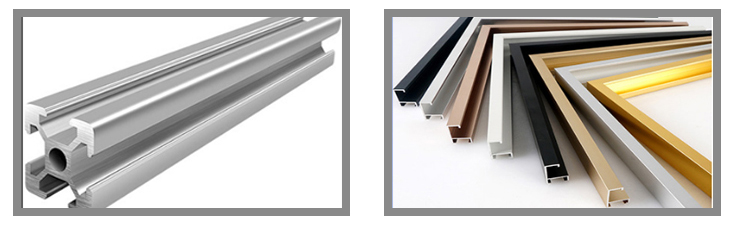

-milling machines as part of a production line to produce aluminum extrusions, steel forgings, etc.

-making parts from various materials such as wood, plastics and metals.

T series:

V series:

Screw Series:

Two-axis Rall:

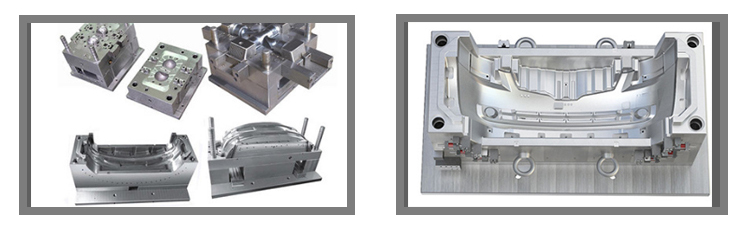

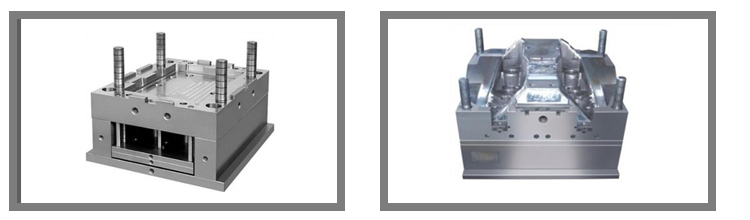

Mould Series:

T series:

V series:

Screw Series:

Two-axis Rall:

Mould Series:

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More