CNC Milling Machine For Metal VMC1160 China CNC Milling Machine

CNC Milling Machine For Metal VMC1160 China CNC Milling Machine.

CNC vertical machining center VMC1890 CNC milling machine for metal

CNC vertical machining center VMC1890 CNC milling machine for metal.

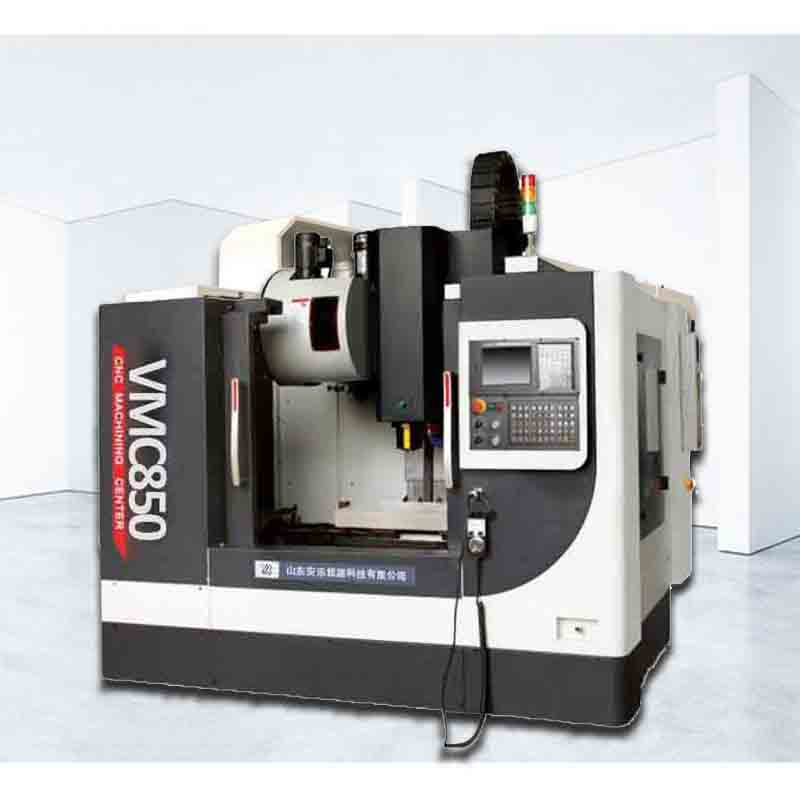

China CNC Milling Machine VMC850 3 Axis CNC Vertical Machining Center

China CNC Milling Machine VMC850 3 Axis CNC Vertical Machining Center.

cnc machine center VMC1280 5 axis cnc milling machine

cnc machine center VMC1280 5 axis cnc milling machine .

3 axis CNC milling machine VMC1270 CNC vertical machining center

3 axis CNC milling machine VMC1270 CNC vertical machining center.

cnc milling machine 5 axis VMC1160 cnc machining center

cnc milling machine 5 axis VMC1160 cnc machining center .

China cnc milling machine VMC1580 cnc machining center

China cnc milling machine VMC1580 cnc machining center.

3 axis cnc milling machine VMC1890 cnc vertical machining center

3 axis cnc milling machine VMC1890 cnc vertical machining center.

cnc machine center VMC850 3 axis cnc milling machine

cnc machine center VMC850 3 axis cnc milling machine.

CNC machine center VMC650 CNC milling machine for metal

CNC machine center VMC650 CNC milling machine for metal.

VMC1160 CNC Milling Machine Metal

VMC1160 cnc milling machine 4 axis can adapt to the processing requirements from .

VMC1160 3 axis metal milling machine

VMC1160 3 axis metal milling machine.The machining center has powerful functions..

VMC1270 cnc milling machine metal

VMC1270 cnc machining center is widely used to produce the auto spare parts, medi.

VMC850 4 axis cnc milling machine

VMC850 cnc milling center has the characteristics of high precision and high effi.

VMC650 3 axis milling machine center

The VMC650 3 axis cnc machine is a bed-type vertical machining center. The large .

VMC1160 vertical cantilever cnc milling machine

VMC1160 vertical CNC machining center is suitable for producing metal product and.

VMC1270 vertical cnc milling machine

Vertical machining center refers to the machining center with the main shaft in a.

Vertical CNC Milling Machines

What is CNC Vertical Milling?

Vertical CNC milling refers to CNC milling operations that utilize vertical milling machines. As suggested by the name, the machines have vertically oriented tooling. This design makes them suitable for use in end milling operations, which use tools with teeth on the periphery and face.

Compared to horizontal CNC milling machines, vertical CNC milling machines offer the following advantages:

They are available at a lower cost (up to four to five times cheaper).

They are easier to use since their design makes it easier to see what is going on with the tooling and workpiece.

They are smaller, which means they require less space in the machine shop.

The simple setup and programming process of CNC vertical equipment allows for straightforward operation and work holding, making it an ideal solution for small parts and short runs.

Vertical milling can be used to produce high-quality precision parts in an array of industries including aerospace, electronics, medical, automotive, and industrial projects. It's ease of setup also makes CNC vertical machining an excellent choice for prototype applications. They are ideal for creating the following:

Box type parts, such as engine blocks, gearboxes, spindle boxes, and gear pump shells

Complex curved parts, such as cams, engine impellers, propellers, and mold cavities

Specialty or irregular parts, such as brackets and bases

CNC Vertical Tools and Machining Variations

Vertically oriented CNC tools are effective for a wide assortment of operations. While vertical mills are the most common type of CNC equipment, other useful tools include:

CNC Vertical Lathes — Available in a wide variety of sizes, these tools can make fast, precise cuts and hold extremely tight tolerances. They can be found combined with machining centers for single setup milling and turning.

CNC Vertical Machining Centers — The most common piece of CNC equipment, these complex tools are the easiest CNC mills to program and a key component of many machine shops. Best for short runs and small sizes, these systems can come fully equipped with an assortment of tools and tool changers, magazines, and carousels. They also offer coolant and fluid systems and specialty enclosures.

CNC 5-Axis Machines — Among the most advanced milling machine centers, these tools can be manipulated across five axes to produce three-dimensional parts with high levels of complexity, precision, and speed for even the most difficult designs.