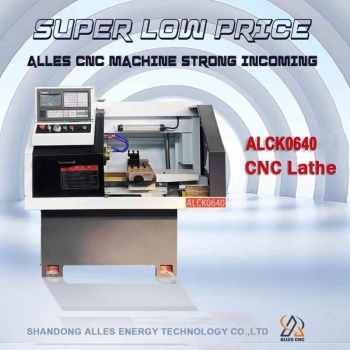

Horizontal Mini Cnc Lathe Machine

Product Description

CNC lathe processing introduce

Characteristic:

(1) Horizontal CNC Lathe horizontal flat bed structure, precision grinding after the surface of the guide rail is quenched, with good precision and precision retention. (2) CNC lathe for metal spindle structure is equipped with high-precision bearings at the same time. Flat bed CNC lathe independent sleeve spindle structure and optional high-precision bearings, cnc lathe 3 axis three-speed gearbox structure. (3)CNC lathe for metal adopts a fully enclosed protective structure, the rigidity of the whole machine is good, and the processing safety, waterproof and dustproof performance are much better than similar products. (4) automatic cnc lathesuitable for processing various shafts, discs and small and medium-sized parts with complex shapes, and is more suitable for the production of large-scale parts with high precision and dimensional consistency requirements.| no | Item | Unit | ALCK0640 |

| 1 | Max swing over bed | mm | Φ250 |

| 2 | Maximum swing over slide | mm | Φ120 |

| 3 | Spindle hole diameter | mm | Φ48 |

| 4 |

With hollow chuck pull rod through hole |

mm | Φ40 |

| 5 | Spindle speed limit | rpm | 3000 |

| 6 | Z stroke | mm | 220 |

| 7 |

X axis repeat positioning accuracy |

mm | 0.01 |

| 8 |

Z axis repeat positioning accuracy |

mm | 0.01 |

| 9 | Machine weight | Kg | 800 |

| 10 | Dimensions (length × width × height) | mm | 1620×1340×1680mm |

| 11 | Control system | GSKTB3 |

Device Configuration

CNC lathes are increasingly widely used in machining due to their advantages of high precision, high efficiency, and ability to adapt to the processing of small batches of multiple varieties of complex parts. To sum up, the processing of CNC lathes has the following advantages.

1. Strong adaptability

When changing the machining parts on CNC lathe for metal, it is only necessary to reprogram the program and input the new program to realize the machining of the new parts without changing the hardware of the mechanical part and the control part, and the production process is completed automatically of. This provides great convenience for single-piece and small-batch production of complex structural parts and trial production of new products.

2. High machining accuracy and stable quality

The automatic cnc lathe is processed according to the instructions given in digital form. Generally, the processing process does not require manual intervention, which eliminates the error caused by the operator. When designing and manufacturing CNC machine tools, many measures have been taken to make the mechanical parts of CNC machine tools have high precision and rigidity, and the backlash of the feed transmission chain and lead screw pitch error can be compensated by the CNC device.

3. Can realize complex movements.

Ordinary lathes are difficult or impossible to realize the movement of curves or curved surfaces with more than three trajectories, such as propellers, steam turbine blades and other spatial surfaces; while CNC lathes can realize almost any trajectory movement and process any shape of space curved surface , adapt to For the processing of complex special-shaped parts.4. High production efficiency.

The time required for parts processing mainly includes two parts: maneuver time and auxiliary time. The range of rotation speed and feed of cnc lathe 3 axis is larger than that of ordinary machine tools, so each process of CNC lathe can choose more favorable cutting amount . Since the CNC lathe has a good structure, it allows strong cutting with a large amount of cutting, which improves the cutting efficiency of the CNC lathe and saves maneuvering time. The moving parts of the CNC lathe have fast idle travel speed, short workpiece clamping time, automatic tool replacement, and greatly reduced auxiliary time compared with ordinary machine tools.5. Good economic benefits.

Horizontal CNC Lathe machining parts can save man-hours for marking, reduce adjustment, processing and inspection time, save direct production costs, generally do not need to make special fixtures, save process equipment costs; CNC machine tools have stable machining accuracy, reduce scrap rates, and make production easier Costs fall further.Aorizontal Cnc Iathe Application

Application areas of CNC technology: The major of CNC technology is mainly for machinery, mold, electronics, electrical, light industry and other industries.You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More