Application of CNC lathe

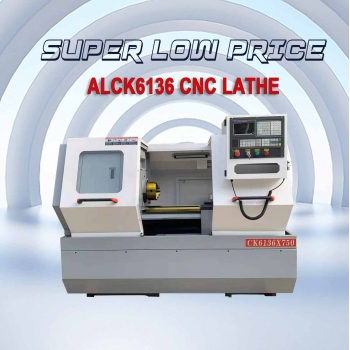

Product Description

CNC Iathe Processing Introduce

CNC turning center is a high-efficiency automatic machine tool composed of mechanical equipment and numerical control system suitable for processing complex parts. CNC turning center is one of the most productive and widely used CNC machine tools in the world. Its comprehensive processing ability is strong , the workpiece can complete more processing content after one clamping, and the processing accuracy is high. For batch workpieces with moderate processing difficulty, its efficiency is 5 to 10 times that of ordinary equipment, especially it can complete The processing that many ordinary equipment cannot complete is more suitable for single-piece processing or medium and small batch multi-variety production with complex shapes and high precision requirements. It concentrates the functions of milling, boring, drilling, tapping and thread cutting on one equipment, making it have a variety of milling of technological means. Machining centers are classified according to the spatial position of the s pindle during

The Main Features Of Horizontal CNC Lathe:

1. Full protective sheet metal design, beautiful and practical. The spindle pressure regulating gauge and the valve are located in front, which is easy to operate. Hollow sheet metal to reserve position and space for the installation of the manipulator.

2. The two ends of the flat bed CNC lathe screw are designed with double pre-tensioning to improve the precision and stability of the cnc lathe 3 axis.

Equipment Configuration and Parameters

| no | Item | Unit | ALCK6136-750 |

| Max swing over bed | mm | Φ360 | |

| Maximum diameter turning on the tool post | mm | Φ200 | |

| Maximum workpiece length between two centers | mm | 750 | |

| Spindle through hole diameter | mm | Φ52 | |

| Spindle speed range (infinite): | r/min | 150-2000 | |

| Spindle end model ISO (GB) | A2-6 | ||

| Spindle motor power | kw | 5.5 | |

| CNC tool holder | Vertical four-station tool holder | ||

| Tool handle size | mm | 20×20 | |

| X stroke | mm | 200 | |

| Z stroke | mm | 750 | |

| Minimum setting unit | mm | 0.01 | |

| Overall dimensions of machine tool (length×width×height) | mm | 2350mm×1380mm×1640mm | |

| Net weight | Seen | 1600 |

The cnc turning center can reduce the number of workpiece clamping, eliminate the positioning error caused by multiple clamping, and improve the machining accuracy. (Drilling and tapping center) When the positional accuracy of each processing part of the part is required to be high, the machining center can process each part in one clamping. The machining center has high processing precision and stable processing quality, which avoids multiple loading of the workpiece. The positioning error caused by the clamp.

1.CNC turning center mostly adopts semi-closed loop or even fully closed loop position compensation function, which has high positioning accuracy and repeated positioning accuracy. The dimensional error generated in the processing process can be compensated in time. Compared with ordinary machine tools, it can obtain higher accuracy. dimensional accuracy.

2.The automatic tool change function of the mini metal lathe can effectively reduce the number of clamping of the workpiece and reduce or eliminate the positioning caused by multiple clamping.

3.CNC lathe for metal has strong adaptability and flexibility. It can be easily solidified on the machining center. In addition, the use of machining center processing can also reduce the auxiliary time for loading and unloading workpieces, save a lot of special and general process equipment , and reduce production costs.

CNC Iathe Application

This series of products is widely used in the machining of automobiles, petroleum and military industries and other industries, and is a famous brand product selected by the first domestic user.You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More