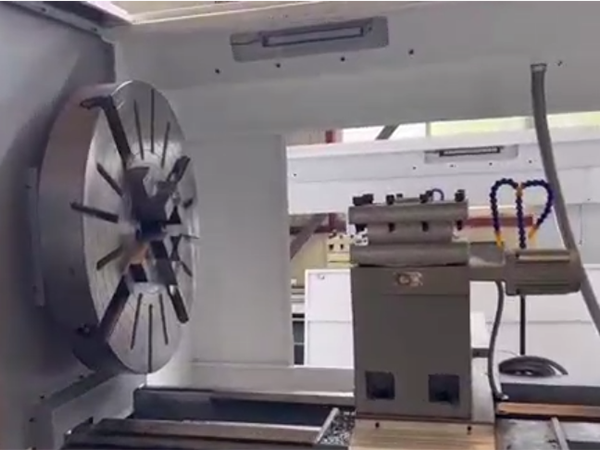

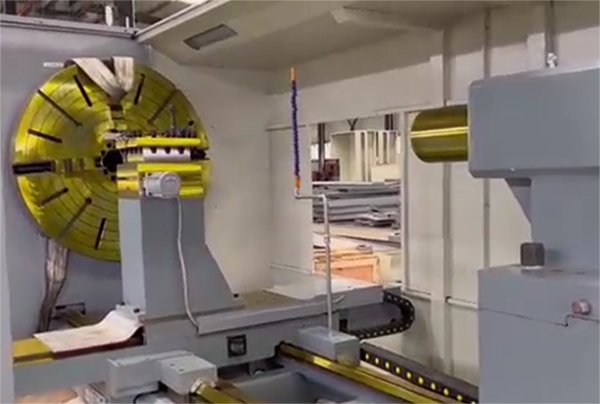

CK61125E heavy duty cnc automatic flat bed cnc turning lathe machine

CK61125E horizontal cnc lathe machines are heavy-duty CNC machine tools, which are automatic metal processing equipment controlled by CNC system. They are suitable for semi-finishing and finishing of heavy workpieces. They have the characteristics of simple programming, reliable structure, convenient operation and high degree of automation.

Product Description

CK61125E heavy duty cnc automatic flat bed cnc turning lathe machine

product description:

CK61125E cnc metal lathe is suitable for processing various heavy-duty and complex shafts, sleeves and disc parts, such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, threading, etc. Easy to program and simple to operate, it is ideal for heavy machining.

CNC Lathe Machine ——CNC Horizontal Lathe Machine

Video:

CNC Lathe Machine ——CNC Horizontal Lathe Machine

Video:

Product Specifications:

Product Specifications:

| Model | Unit | Parameter |

| ALCK61125E/1000 | ||

| Maximum turning diameter of bed | mm | Φ1250 |

| Swing over cross slide | mm | Φ650 |

| Max. processing length | mm | 1500 |

| X/Z axis travel | mm | X:650 Z:1350 |

| Spindle nose | A2-15 | |

| Spindle bore | mm | Φ130 |

| Spindle motor | Kw | 22 |

| X/Z Rapid traverse | mm | 4/5 |

| X/Z axis repeatability | mm | ±0.005 |

| Tailstock sleeve dia. | mm | Φ160 |

| Quill traverse | mm | 250 |

| Cutting tool size | m/min | 40×40 |

| X/Z axis feed motor torque | mm | 15 |

| Machine Net Weight | Kg | 8200 |

| Machine Size(L×W×H) | mm | 4065×2355×2425 |

Product advantages:

1. The overall bed is cast by resin sand process, and after aging treatment, it has beautiful appearance, good rigidity and high precision

2. The surface of the guide rail is quenched by ultrasonic frequency, which has extremely high precision retention, high hardness and long life.

3. High-quality scraper board is used to prevent the guide rail from being scratched, and the guide rail surface is covered with plastic, which has good wear resistance and high precision.

CK61125E CNC Lathe factory

Video:

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More