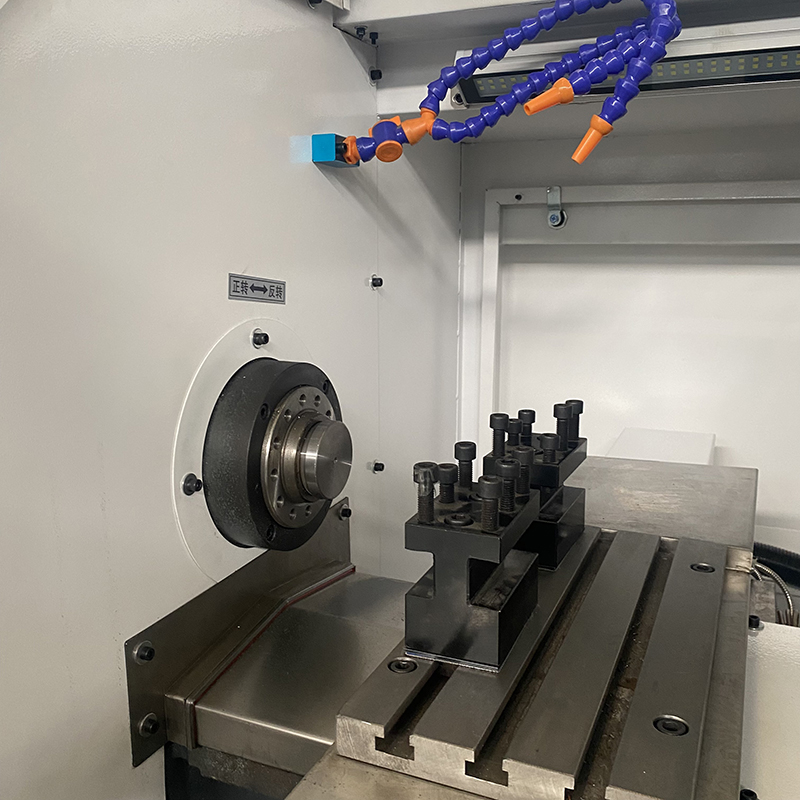

CK0640 mini lathe milling machine

CK0640 high precision cnc lathe adopts the design of mechatronics, which can automatically complete the cutting of internal and external circles, end faces, grooving, chamfering, drilling, arbitrary tapered surfaces, spherical surfaces and various inch and metric threads of various parts. Widely used in automobile and motorcycle accessories, valves, plumbing pipes, hardware tools, clocks, electrical appliances, avionics and other industries.

Product Description

CK0640 mini lathe milling machine

Product description:

CK0640 CNC lathe automatic small precision horizontal flat bed has the characteristics of practicality, convenient operation and high machining accuracy. CK0640 high precision cnc lathe can realize the processing of complex parts such as straight lines, tapers, arcs, threads, etc. CK0640 automatic cnc lathe machine is especially suitable for single and mass production products with complex shapes.

Video:

Product Specifications:

| Item | Unit | Parameter |

| ALCK0640 | ||

| Max swing over bed | mm | Φ250 |

| Maximum swing over slide | mm | Φ120 |

| Spindle hole diameter | mm | Φ48 |

| With hollow chuck pull rod through hole | mm | Φ40 |

| Spindle speed limit | rpm | 3000 |

| Knife square size | mm | □20×20 (four stations) |

| X/Z direction fast moving speed | m/min | 6/8 |

| X stroke | mm | 200(Optional 300/400mm) |

| Z stroke | mm | 220 |

| Main motor power | KW | 3(Optional 4kw) |

| X axis repeat positioning accuracy | mm | 0.01 |

| Z axis repeat positioning accuracy | mm | 0.01 |

| Machine weight | Kg | 800 |

| Dimensions (length × width × height) | mm | 1620×1340×1680mm |

Product advantages:

1. The spindle adopts high-speed contact bearing, which can achieve higher cutting speed during processing;

2. The standard spring chuck is fast and easy to tighten;

3. The bed adopts double-mountain guide rail, which has high guiding precision and can automatically compensate for the gap even if it is worn;

4. The guide rail is quenched with super audio frequency and has a long service life.

Video:

Video:

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More