Flat bed cnc lathe CK6140X750 Machinable metal fittings

Product Description

High precision cnc lathe makes the cutting tool contact with the workpiece by continuous cutting, so that the workpiece achieves a better outer surface. The Allescnclathe flat bed cnc lathe machine is mainly used for machining inner and outer cylindrical or conical surfaces such as shafts, bushings and sleeves.

Features of CNC Lathe Metal:

1. CNC lathe has high processing precision and good stability; metal CNC lathe has high precision and high rigidity, and is several times more efficient than manual lathe production.

2. The cnc lathe machine has strong adaptability to the processing object, adapts to the characteristics of single-piece production of molds and other products, and provides a suitable processing method for the manufacture of molds.

3. When the processing parts of cnc lathe machine price are changed, it is only necessary to change the numerical control program, which can save production time. CNC lathe machining and multi-coordinate linkage can process parts with complex shapes.

4. The alloy wheel cnc lathe is conducive to the modernization of production management. CNC machine tools use digital information and standard codes to process and transmit information, and use computer control methods, which lays the foundation for the integration of computer-aided design, manufacturing and management.

What measuring tools are needed in cnc lathe turning repairs?

(1) Inspection bridge plate, length 250mm, quantity 1, used to measure the accuracy of the bed guide of the cnc lathe tool holder.

(2) Angle base, length 200-250mm, quantity 1, used for scraping, grinding, and measuring cnc lathe processing bed rails.

(3) Angle base, 200x250mm, quantity 1, used for scraping and grinding, and used for measuring the bed guide of mini cnc lathe machine.

(4) Inspection mandrel, Φ80×1500 mm, quantity 1, used to measure the straightness of the guide rail of the cnc lathe fanuc bed.

(5) Inspection mandrel, Φ30×300 mm, quantity 1, used to measure the parallelism of the screw hole of the slide to the guide rail.

(6) Angle base, length 200mm, quantity 1, used for scraping and grinding slide dovetail guide.

(7) Angle base, length 150mm, quantity 1, use mini cnc lathe machine to scrape and grind the sliding plate dove box tail rail.

(8) Inspection mandrel, Φ50×300 mm, quantity 1, used to measure the axis of the opening and closing nut.

(9) Grinding rod, quantity 1, for grinding horizontal cnc lathe

Tailstock shaft hole.

(10) Check the mandrel, Φ30×190 mm, Φ30×225 mm, 1 each in quantity, used to measure the coaxiality of the three supports.

(11) Measuring tools, 1 set.

Video

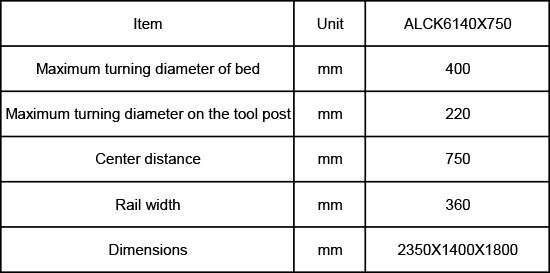

Technical parameters

Video

Technical parameters

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More