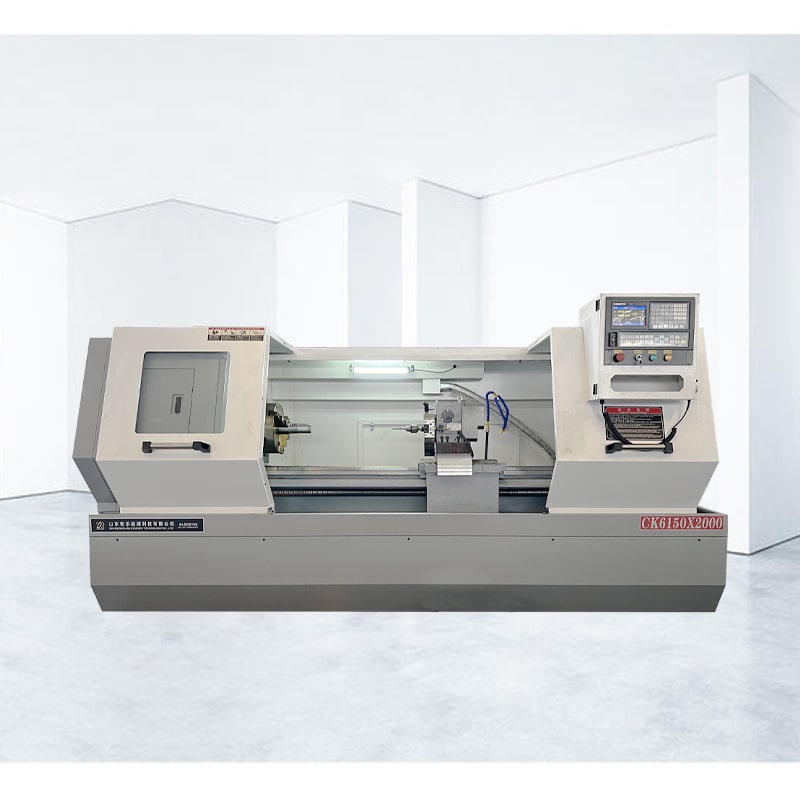

CNC Lathe ALCK6150x2000 CNC lathe for metal

Product Description

Horizontal CNC Lathe ALCK6150x2000 has a variety of functions and operation options, suitable for a wide range of machining needs. Whether it is outer circle, inner circle, thread, or complex surface processing, ALCK6160x1000 flat bed CNC lathe can flexibly respond to meet the processing requirements of different industries.

Features:

1. ALCK6150x2000 Flat bed CNC lathe adopts advanced CNC control system, which can realize sub-millimeter precision machining. Whether it is a small part or a complex surface, it can get precise machining results.

2. The tool post system equipped with CNC lathe for metal can automatically switch different tools to realize various cutting methods, such as turning, boring, tapping and so on. It can adapt to different workpiece shapes and processing requirements and improve production efficiency.

3. ALCK6150x2000 Horizontal CNC Lathe is equipped with high-speed spindle and fast feed system, which can greatly improve processing speed and production efficiency. It is suitable for mass production and urgent delivery scenarios, greatly shortening the processing cycle.

4. The CNC control system equipped with CNC lathe for metal can automatically realize the machining process according to the pre-programmed instructions. With flexible production scheduling and automatic control, it reduces the interference of human factors and improves work efficiency.

CNC lathe CK6150 application:

Video

CNC lathe CK6150 application:

1. Automobile manufacturing industry: Flat bed CNC lathe is used for processing automobile engine parts, chassis parts, etc.

2. Aerospace industry: CNC lathe for metal is used to process aircraft parts, aero engine components, etc.

3. Mold manufacturing: Flat bed CNC lathe is used to make various molds, such as plastic molds, casting molds, etc.

4. General machinery manufacturing: CNC lathe for metal is used to process various mechanical parts to meet the needs of different industries.

CNC lathe ALCK6150x2000 optional configuration:

1. Control system: Optional control systems include common CNC systems, such as Fanuc, Siemens, GSK, etc. Different control systems may have different functions and user interfaces.

2. Spindle type: Different types of spindles can be selected according to processing requirements, such as direct drive spindles, spindles with gear transmission, etc. Each spindle type has a different speed range and torque output.

3. Type of turret: The turret is a component for loading cutting tools. The optional turret types include four-station turret, eight-station turret, electric turret, etc. Different types of turrets can accommodate different numbers and types of tools, providing greater processing flexibility.

4. Automatic tool change system: The automatic tool change system can improve production efficiency and automation level. Optional automatic tool change systems include servo tool changers, mechanical tool changers, and more for quick and accurate cutting tool changes.

5. Tailstock type: The tailstock is a part used to support and fix the workpiece, and the optional tailstock types include manual tailstock and hydraulic tailstock. Hydraulic tailstocks generally offer greater precision and stability.

6.Processing auxiliary devices: According to specific needs, some processing auxiliary devices can also be selected, such as automatic feeding devices, tool measuring systems, coolant systems, etc., to improve processing efficiency and quality.

Product Specifications

| Model | Unit | ALCK6150x2000 |

|

The maximum turning diameter on the bed:

|

mm | Φ500 |

| Maximum cutting diameter: | mm | Φ500 |

| Maximum processing length: | mm | 2000 |

| X/Z axis maximum stroke: | mm | 2000 |

| X/Z axis minimum displacement unit: | mm | 0.001 |

| Spindle aperture: | mm | Φ82 |

| Spindle speed limit: | rpm | 150-2000/60-1600 |

| Maximum turning diameter on the carriage: | mm | Φ290 |

| Main motor power (frequency conversion): | kw | 7.5 |

| Inverter: | kw | 7.5 |

| X/Z axis: | N.m | 5/7.5 |

| X/Z axis moving speed: | m/min | 6/8 |

| Tailstock sleeve diameter: | mm | Φ65 |

| Tailstock sleeve stroke: | mm | 130 |

| Power demand (power/current): | kW/20A | 15 |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More

Horizontal CNC Lathe ALCK6150x2000 adopts advanced numerical control technology and precise electronic control system, which can realize high-precision machining at millimeter level.

Horizontal CNC Lathe ALCK6150x2000 adopts advanced numerical control technology and precise electronic control system, which can realize high-precision machining at millimeter level.