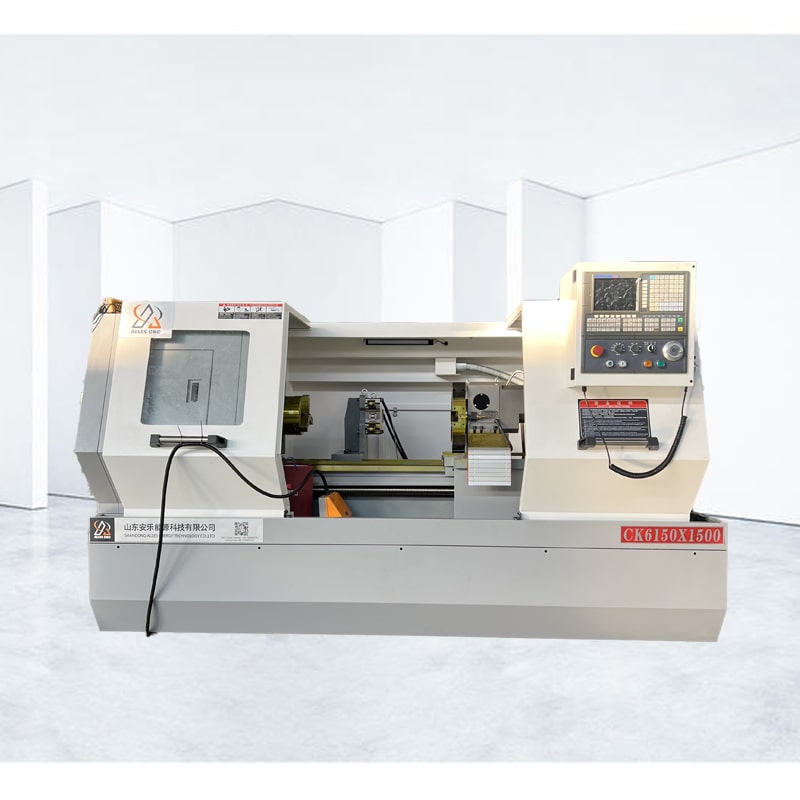

Horizontal CNC Lathe ALCK6150 Automatic cnc lathe

Product Description

CNC lathe for metal ALCK6150 has become the first choice equipment for precision machining in various industries due to its excellent technical features and wide application fields, contributing to the improvement of production efficiency and product quality.

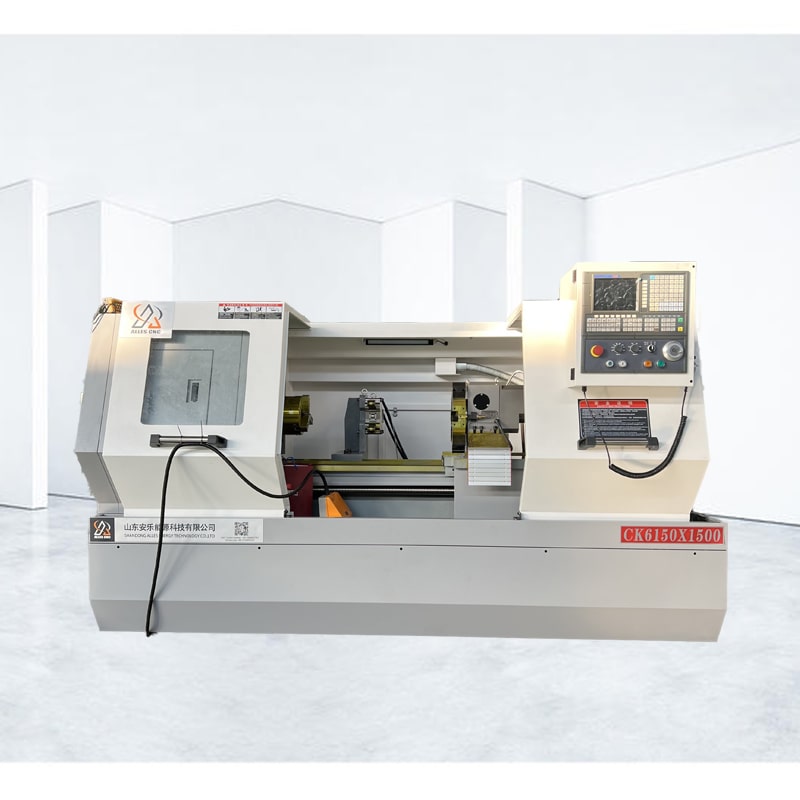

feature:

1. High-precision machining: Horizontal CNC Lathe ALCK6150 adopts advanced numerical control technology, which can realize micron-level precision machining, and ensure that the size and surface quality of the workpiece reach a very high level.

2. Multifunctional processing: CNC lathe for metal has multi-axis linkage function, which can perform complex contour processing, internal and external thread processing, hole processing and other processing operations, which improves the flexibility and efficiency of processing.

3. Stable performance: Horizontal CNC Lathe ALCK6150 is equipped with high-performance spindle and drive system, with stable speed and cutting ability, suitable for processing various metal materials.

4. Intelligent operation: CNC lathe for metal is equipped with intuitive CNC operation interface, which is easy to operate, and can also preset processing parameters to realize automatic processing process and reduce operation difficulty.

5. High rigidity structure: The Horizontal CNC Lathe machine tool has a solid structure, which can withstand high-load cutting forces and maintain stable machining accuracy and surface quality.

CNC lathe CK6150 application:

1. Aerospace: Horizontal CNC Lathe is used to process aero-engine parts, spacecraft components, etc., to meet the stringent requirements for high precision and high reliability.

2. Automobile manufacturing: CNC lathe for metal is suitable for the production of precision parts such as automobile engines, gearboxes, transmission systems, etc., to improve the performance and reliability of automobiles.

3. Mold manufacturing: Horizontal CNC Lathe is used to make complex molds, such as plastic molds, die-casting molds, etc., to ensure the accuracy and life of the molds.

4. Energy equipment: CNC lathe for metal can process various energy equipment parts, such as generator shafts, turbine blades, etc., to ensure the efficient operation of energy equipment.

5. General machinery: Horizontal CNC Lathe provides high-precision machining solutions in the field of general machinery manufacturing, such as the processing of bearings and gears.

Video

Video

Possible configuration options for CNC lathe ALCK6150x1500:

1. Control system: Optional control systems include common CNC systems, such as Fanuc, Siemens, GSK, etc. Different control systems may have different functions and user interfaces.

2. Spindle type: Different types of spindles can be selected according to processing requirements, such as direct drive spindles, spindles with gear transmission, etc. Each spindle type has a different speed range and torque output.

3. Type of turret: The turret is a component for loading cutting tools. The optional turret types include four-station turret, eight-station turret, electric turret, etc. Different types of turrets can accommodate different numbers and types of tools, providing greater processing flexibility.

4. Automatic tool change system: The automatic tool change system can improve production efficiency and automation level. Optional automatic tool change systems include servo tool changers, mechanical tool changers, and more for quick and accurate cutting tool changes.

5. Tailstock type: The tailstock is a part used to support and fix the workpiece, and the optional tailstock types include manual tailstock and hydraulic tailstock. Hydraulic tailstocks generally offer greater precision and stability.

6.Processing auxiliary devices: According to specific needs, some processing auxiliary devices can also be selected, such as automatic feeding devices, tool measuring systems, coolant systems, etc., to improve processing efficiency and quality.

Product Specifications

Product Specifications

|

Item

|

Unit | ALCK6150*1500 |

| Max swing over bed | mm | Φ500 |

| Maximum swing over slide | mm | Φ290 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1500 |

| X/Z axis maximum stroke | mm | 1500 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Spindle speed limit | rpm | 150-2000/60-1600 |

| Main motor power (frequency conversion) | kW | 7.5 |

| Frequency converter | kW | 7.5 |

| X/Z axis rapid traverse speed | m/min | 6/8 |

| Tool bar size | mm | 25*25 |

| Repeated positioning accuracy of tool post | mm | ≤0.004 |

| Diameter of tailstock sleeve | mm | Φ65 |

| Tailstock sleeve stroke | mm | 130 |

| Electricity demand (power/current) | kW/A | 15kW/20A |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More