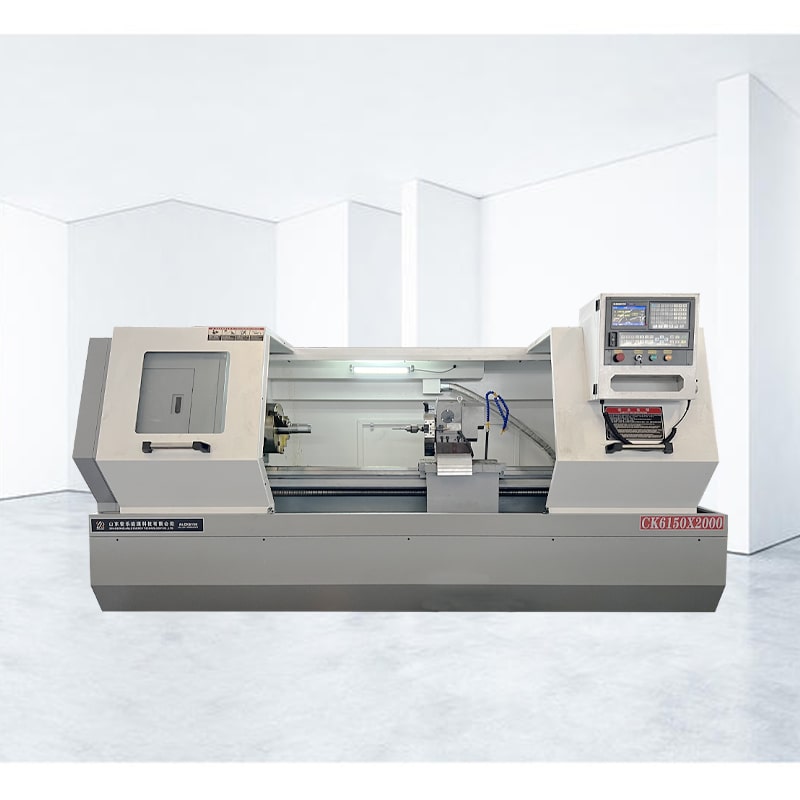

CNC Lathe ALCK6150x2000 CNC lathe for metal

Product Description

CNC lathe for metal ALCK6150x2000, with its unique features and application advantages in the hardware manufacturing industry, provides hardware manufacturers with first-class processing solutions and promotes the excellence of hardware manufacturing.

Features:

1. Ultra-long processing stroke: Automatic cnc lathe ALCK6150x2000 has a processing stroke of 2000 mm, which is suitable for processing larger-sized workpieces and meets various needs in hardware manufacturing.

2. High-efficiency cutting ability: CNC lathe for metal is equipped with a powerful spindle and cutting system, which has stable cutting performance and can easily handle the processing of various metal materials.

3. Multifunctional processing: Automatic cnc lathe supports multi-axis linkage, and can realize complex contour processing, thread processing, hole processing and other processing operations to meet the diverse processing needs in the hardware field.

4. Precise positioning control: CNC lathe for metal ALCK6150x2000 adopts advanced numerical control technology to realize micron-level precise positioning control and ensure high precision of workpiece size and shape.

5. Intelligent operation interface: Automatic cnc lathe is equipped with an intuitive and friendly CNC operation interface, which simplifies the operation process, improves operation efficiency and reduces the operation threshold.

CNC lathe CK6150 application:

1. Shipbuilding: CNC lathe for metal is used to manufacture hardware parts such as hull structural parts and propeller shafts to meet the high-strength requirements of ships under strong environmental pressure.

2. Oil and gas: Horizontal CNC Lathe is suitable for processing key components such as oil drill bits and oil well pipelines to ensure safe and stable production in the oil and gas industry.

3. Construction and infrastructure: CNC lathe for metal is used to process large structural parts, bridge supports, etc., to ensure the stability and durability of infrastructure.

4. Energy equipment: Horizontal CNC Lathe is used to manufacture generator set components, nuclear power equipment accessories, etc., providing stable and efficient core components for the energy industry.

5. Mechanical manufacturing: CNC lathe for metal is used to produce various parts, threaded connections, bearings and other key components.

Video

Video

CNC lathe ALCK6150x2000 optional configuration:

1. Control system: Optional control systems include common CNC systems, such as Fanuc, Siemens, GSK, etc. Different control systems may have different functions and user interfaces.

2. Spindle type: Different types of spindles can be selected according to processing requirements, such as direct drive spindles, spindles with gear transmission, etc. Each spindle type has a different speed range and torque output.

3. Type of turret: The turret is a component for loading cutting tools. The optional turret types include four-station turret, eight-station turret, electric turret, etc. Different types of turrets can accommodate different numbers and types of tools, providing greater processing flexibility.

4. Automatic tool change system: The automatic tool change system can improve production efficiency and automation level. Optional automatic tool change systems include servo tool changers, mechanical tool changers, and more for quick and accurate cutting tool changes.

5. Tailstock type: The tailstock is a part used to support and fix the workpiece, and the optional tailstock types include manual tailstock and hydraulic tailstock. Hydraulic tailstocks generally offer greater precision and stability.

6.Processing auxiliary devices: According to specific needs, some processing auxiliary devices can also be selected, such as automatic feeding devices, tool measuring systems, coolant systems, etc., to improve processing efficiency and quality.

Product Specifications

|

The maximum turning diameter on the bed:

|

Φ500mm |

| Maximum turning diameter on the carriage: | Φ290mm |

| Maximum cutting diameter: | Φ500mm |

| Maximum processing length: | 2000mm |

| X/Z axis maximum stroke: | 2000mm |

| X/Z axis minimum displacement unit: | 0.001mm |

| Spindle aperture: | Φ82mm |

| Spindle speed limit: | 150-2000/60-1600rpm |

| Spindle end: | A2-8/C8 |

| Main motor power (frequency conversion): | 7.5kw |

| Inverter: | 7.5kw |

| X/Z axis: | 5/7.5N.m |

| X/Z axis moving speed: | 6/8m/min |

| Tailstock sleeve diameter: | Φ65mm |

| Tailstock sleeve stroke: | 130mm |

| Power demand (power/current): | 15kW/20A |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More