CNC Lathe Machining Of Auto Parts

Product Description

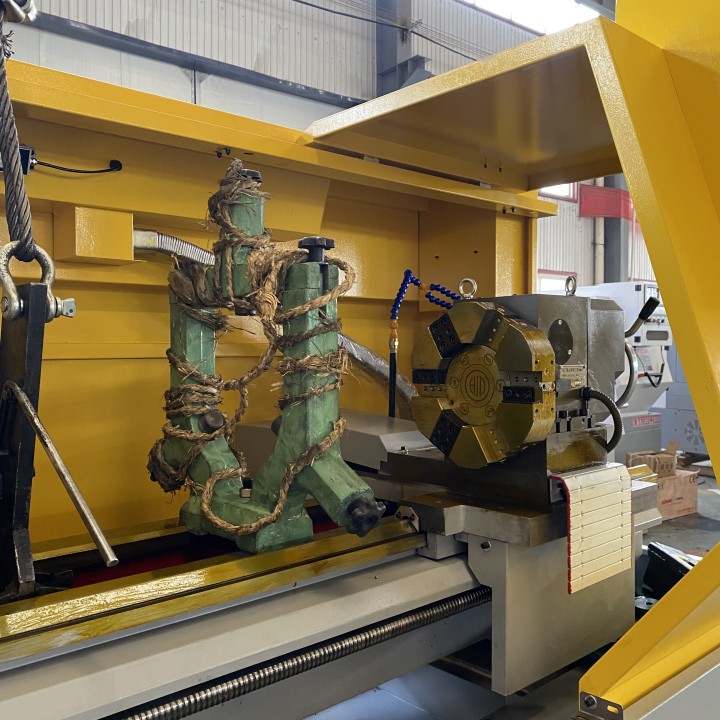

Flatbed CNC lathe has the following characteristics:

High machining precision and stable machining quality;

Multi-coordinate linkage can be carried out, and parts with complex shapes can be processed;

When the machining parts are changed, generally only the NC program needs to be changed, which can save production preparation time;

The CNC lathe for metal itself has high precision and high rigidity, and can choose favorable processing amount, and the productivity is high (generally 3~5 times of ordinary machine tools);

CNC lathe processing has a high degree of automation, which can reduce labor intensity;

Higher quality requirements for operators and higher technical requirements for maintenance personnel.

CNC lathe For Metal Function And Feature Description

Metal CNC lathes are easy to operate, safe to protect, novel and beautiful in appearance, easy to maintain and easy to maintain.

CNC lathe processing has strong adaptability to processing objects, adapts to the characteristics of single-piece production of molds and other products, and provides suitable processing methods for mold manufacturing;

Equipment Configuration And Parameters

| Item | Unit | ALCK6150*1500 |

| Max swing over bed | mm | Φ500 |

| Maximum swing over slide | mm | Φ290 |

| Maximum cutting diameter | mm | Φ500 |

| Maximum processing length | mm | 1500 |

| X/Z axis maximum stroke | mm | 1500 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Spindle speed limit | rpm | 150-2000/60-1600 |

| X/Z axis rapid traverse speed | m/min | 6/8 |

| Tool bar size | mm | 25*25 |

| Diameter of tailstock sleeve | mm | Φ65 |

| Tailstock sleeve stroke | mm | 130 |

Accessories

Vertical Machining Center CNC Lathe Machine Factory The vertical machining center has the characteristics of high productivity and authenticity. All castings of high ALLEs CNC must pass the test of time to be suitable for vertical machining machine tools such as precision, convenient programming and environmental protection. All parts must be secondary tempered. The post-machine center is suitable for machining and mold making. It can adapt the machine to work continuously for 72 hours without processing. From rough machining to finishing machining requirements, the workpiece can also be finished machining to ensure that the machine can be used normally. Multiple processes, such as milling, drilling, tapping, boring, etc. The warehouse covers an area of about 4000 square meters. Equipped with various factory production parts, outsourced parts and CNC systems. GSK system purchases about 200-300 sets at a time, the system is in stock, and the yield rate is very high.

Flat Bed CNC Lathe Advantages

High speed and precision are the eternal goals of cnc lathe 3 axis development. With the rapid development of science and technology, the speed of replacement of electromechanical products is accelerated, and the requirements for the precision and surface quality of parts processing are also higher and higher.

In order to meet the needs of this complex and changeable market, the current automatic cnc lathe is developing in the direction of high-speed cutting, dry cutting and quasi-dry cutting, and the machining accuracy is constantly improving.

Application Of Cnc Lathe

CNC lathe sed to process and manufacture high-precision and complex components such as electrical appliances, etc.You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More