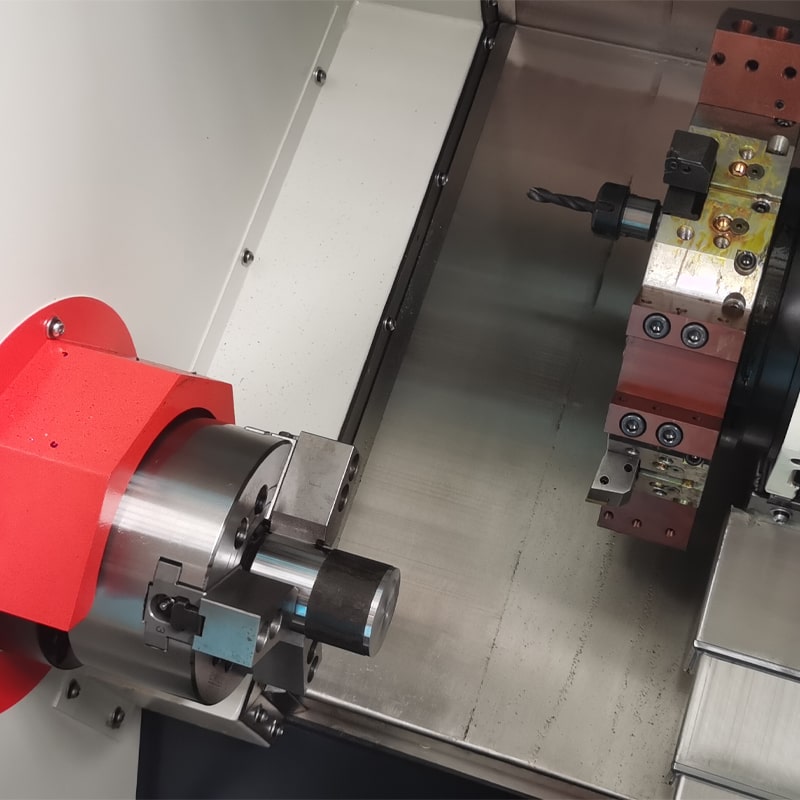

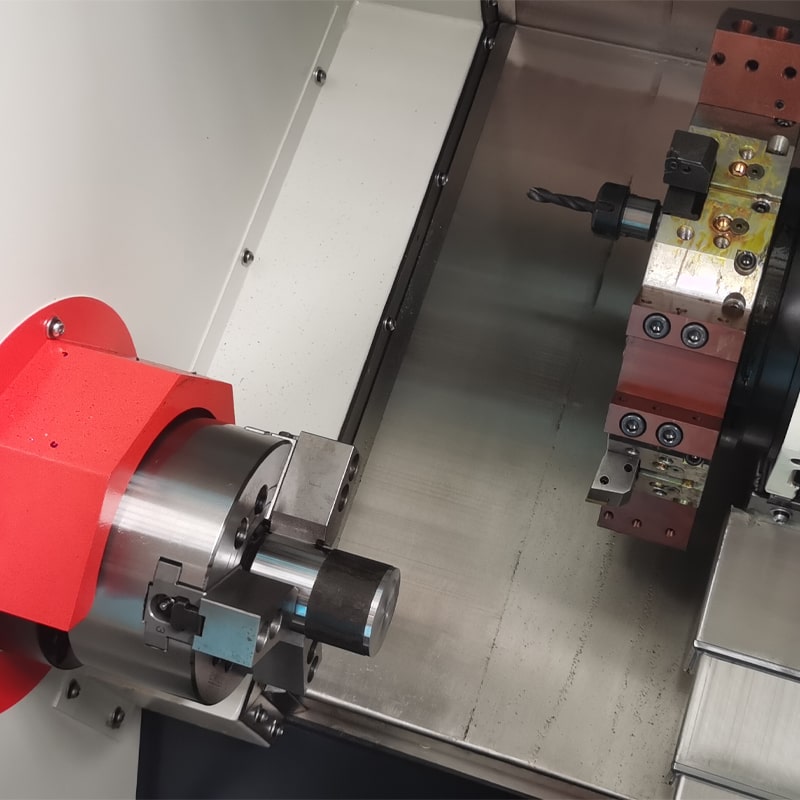

Slant bed cnc lathe machine ALTCK46A metal lathe machine

Product Description

The CNC lathe can automatically complete the processing of rotating parts such as shafts and discs through the operation of the CNC machining program.

Metal cnc lathe machine has a wide range of processing capabilities, and can process straight cylinders, oblique cylinders, arcs and various threads.

Metal slant bed cnc lathe machine has various compensation functions of linear interpolation and circular interpolation, and has played a good economical effect in the mass production of complex parts.

CNC horizontal lathe features of high production efficiency

The time required for part processing consists of two parts: actual cutting and auxiliary time. Because high precision cnc lathe can achieve large cutting amount, high line speed cutting and fast dry running speed, the processing production efficiency of cnc lathe manufacture is much higher than that of ordinary lathes.

The cnc lathe machine generally has good rigidity, which allows strong cutting with a large amount of cutting, saving roughing time.

The mini cnc lathe machine can realize infinitely variable speed. In this way, the range of rotation speed selection and adjustment is widened, and a better linear speed can be obtained.

These favorable conditions provide a reliable guarantee for increased productivity.

When the production volume is medium batch, cnc mini metal lathe can show its superiority even more.

Automatic cnc lathe can machine parts of revolution with special threads

The types of threads that can be turned by a common lathe are limited. It can only turn straight and tapered metric and inch threads with equal leads, and a lathe can only be limited to a number of leads.

The slant bed cnc lathe machine can not only turn various equal-lead straight, tapered and end-face threads, but also turn the threads with increased lead, reduced lead, and smooth transition between equal lead and variable lead. And high-precision modular helical parts (such as worms).

When the cnc slant bed lathe machine turns threads, the rotation of the spindle does not need to be changed alternately like ordinary lathes, the cnc lathe slant bed machine can continuously cycle and cut until it is completed, so the thread turning efficiency is very high.

The cnc lathe machine slant bed is equipped with the function of pitch compensation, coupled with the use of carbide forming inserts, and the use of higher rotational speeds, so the thread turning precision is high and the surface roughness value is small.

Product Parameters

Product Parameters

| Item | ALTCK46A |

| Maximum upper turning diameter of bed | Φ460mm |

| Maximum machining diameter on tool post | Φ170mm |

| Maximum processing length | 350mm |

| Spindle head type (optional chuck) | A2-5 |

| Spindle motor power | 5.5KW |

| Spindle speed | 3500pm |

| Spindle hole diameter | Φ56mm |

| Bar diameter | Φ45mm |

| X axis limit stroke | 240mm |

| The X/Z axis screw specifications | 3210/4010 |

| The X-axis limit stroke | 240mm |

| The Z axis stroke limit | 400mm |

| The X axis motor torque | 7.5N.m |

| The Z axis motor torque | 7.5N.m |

| X/Z axis repeatability | ±0.003mm |

| Maximum stroke of tailstock | 200mm |

| length * width * height (mm) | 2500×1700×1890mm |

| Weight (approximate weight) | 2600kg |

You May Also Like

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine

China CNC Milling Machine VMC1580 Fanuc CNC Controller VMC Machine… Read More